Proper Use of a Torque Wrench for Lug Nuts: Safety, Accuracy, and Maintenance

Proper Use of a Torque Wrench for Lug Nuts: Safety, Accuracy, and Maintenance

When it comes to wheel installation and maintenance, torque accuracy is not optional—it is a safety-critical requirement.

At SAIVS, we emphasize the correct use of torque wrenches to prevent damage to components and to protect drivers on the road.

This article explains how to use a torque wrench properly, the mistakes to avoid, and the intervals for checking and retorquing lug nuts.

Why Torque Accuracy Matters

Lug nuts secure the wheel to the hub, ensuring proper clamping force across the wheel face.

Incorrect torque can cause failures ranging from warped brake rotors to loose wheels that compromise vehicle safety.

A calibrated torque wrench and correct procedures give both reliability and peace of mind.

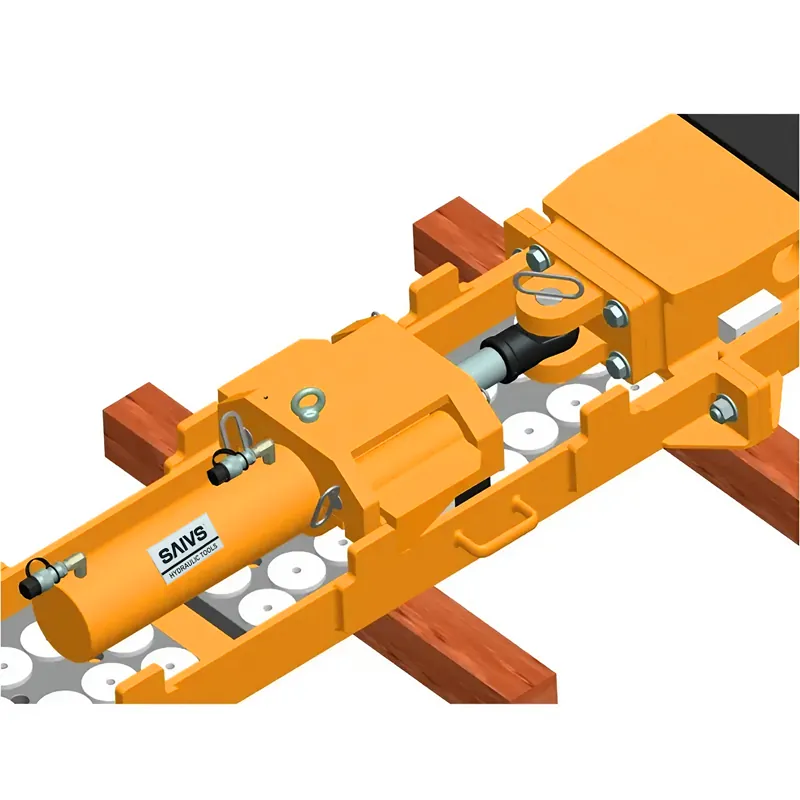

SHW Series, Hexagon Cassettes for Low Profile Hexagon Torque Wrenches

Critical Mistakes to Avoid with Torque Wrenches

Over-Tightening Lug Nuts

Applying too much torque stretches the studs and risks permanent deformation.

Over-clamping may also warp brake rotors, leading to vibration and reduced stopping performance.

Under-Tightening Lug Nuts

Failure to reach the required torque can allow the wheel to move under load.

In severe cases, this can cause wheel separation, an extremely dangerous road hazard.

Using the Torque Wrench as a Breaker Bar

Never use your torque wrench to loosen stubborn nuts.

The internal calibration spring and ratcheting mechanism are designed for precision tightening, not high-force breakaway torque.

Forgetting to Reset After Use

Click-type torque wrenches rely on a spring mechanism.

Storing the wrench at a high setting fatigues the spring, resulting in inaccurate torque readings over time.

Incorrect Tightening Sequence

Following the wrong tightening sequence leads to uneven pressure distribution.

Always use a star or cross pattern in gradual torque steps to ensure the wheel seats flat against the hub.

Impact Sockets for Square Drive Hydraulic Torque Wrench

How Often Should You Retorque Lug Nuts?

Torque changes due to heat, vibration, and load cycles.

To maintain safety, follow these guidelines:

- 50–100 miles after wheel installation or rotation

- Before long trips or when towing heavy loads

- During scheduled maintenance checks

- Whenever vibration or unusual wheel noise occurs

For fleet and industrial vehicles, SAIVS recommends building a documented torque inspection schedule tailored to your usage conditions.

Best Practices for Long-Term Accuracy

Use clean hardware. Always remove dirt, rust, and paint from wheel seats and hub faces.

Avoid lubrication. Unless specified by the manufacturer, install lug nuts dry to prevent over-tightening due to reduced friction.

Tighten gradually. Step torque values in two or three passes, finishing at the specification with a final star-pattern sweep.

Check calibration. Professional torque tools should be calibrated at least once per year or after any impact drop.

Store properly. Reset the wrench to its lowest setting and keep it in a protective case away from moisture and dust.

SAIVS Torque Tools: Built for Reliability

SAIVS offers a wide range of torque wrenches—click, beam, and digital—engineered for precision and durability.

Each tool is designed for heavy-duty use in workshops, fleets, and industrial applications where torque integrity is vital.

With calibration support and a full range of sockets and accessories, SAIVS ensures you always work within safe, verified limits.

Partner with SAIVS for Safer Operations

From passenger cars to heavy equipment, correct lug nut torque is essential for safety, reliability, and compliance.

Contact SAIVS today for professional torque wrenches and accessories that protect your wheels, reduce downtime, and improve performance.