Precision Torque Control with Hydraulic Wrenches for High-Reliability Industrial Bolting

The Importance of Accurate Torque in industrial applications

In industrial bolting operations, torque accuracy directly affects safety and reliability.

Improper torque can cause leaks, structural deformation, or premature equipment failure.

Industries such as oil and gas, power generation, shipbuilding, and heavy manufacturing rely on precise torque control to maintain joint integrity.

Hydraulic Torque Wrenches provide a controlled and repeatable solution for these demanding environments.

Compared with manual tools, Hydraulic Systems deliver consistent output regardless of operator strength or fatigue.

How Hydraulic torque wrenches Improve Bolting Accuracy

Controlled Torque Output

hydraulic torque wrenches use pressurized fluid to generate rotational force.

This allows torque to be applied smoothly without sudden force spikes.

As a result, fasteners reach the target torque value without overshoot.

Preset Torque Adjustment

Operators can set a specific torque value before tightening begins.

This eliminates guesswork and reduces dependency on operator experience.

Once the set value is reached, hydraulic pressure stops automatically.

Consistent Performance Across Multiple Fasteners

Manual tightening often produces uneven torque across a flange or joint.

hydraulic tools maintain uniform torque from bolt to bolt.

This consistency improves load distribution and reduces long-term joint stress.

Advantages Over Traditional Manual Torque Tools

Reduced Human Error

Manual torque tools rely heavily on physical effort and judgment.

Fatigue and awkward working positions increase the risk of incorrect tightening.

Hydraulic systems remove these variables by delivering controlled mechanical force.

Higher Productivity on Site

High torque values can be achieved quickly with hydraulic power.

Technicians complete more bolting tasks in less time.

This improves overall project efficiency and reduces labor costs.

Lower Operator Fatigue

Trigger-based operation requires minimal physical strength.

Operators remain productive during extended work periods.

Reduced fatigue also contributes to safer working conditions.

Engineering Features Designed for Precision

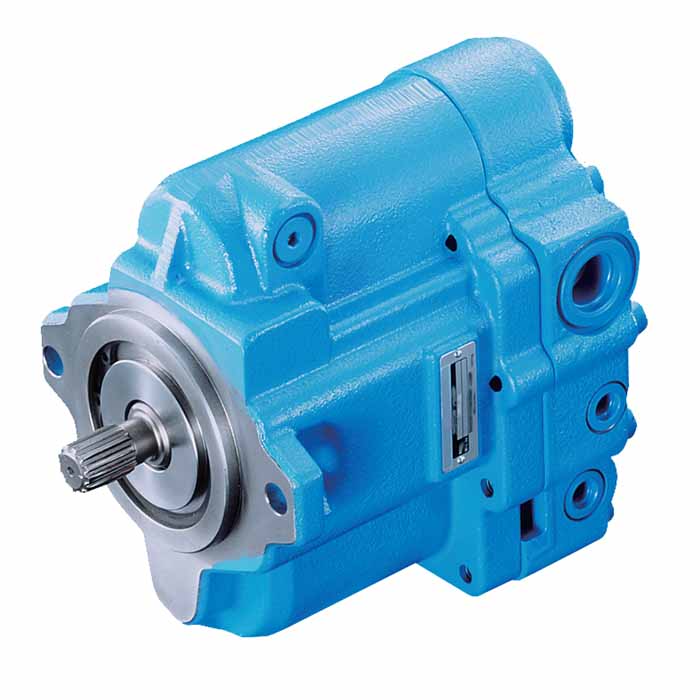

High-Pressure Hydraulic Systems

Internal piston assemblies convert fluid pressure into controlled rotation.

Precision-machined components ensure smooth movement under high loads.

This design supports accurate torque delivery even in extreme conditions.

Durable Sealing Technology

Industrial-grade seals prevent hydraulic fluid leakage.

Stable pressure is maintained throughout the tightening process.

This protects internal components and ensures long service life.

Overload Protection Mechanisms

Built-in pressure relief valves protect tools from excessive force.

This feature prevents damage caused by unexpected resistance or misuse.

It also adds an extra layer of operator safety.

Calibration and Traceability in Critical Bolting

Accurate torque depends on regular calibration.

Hydraulic torque wrenches are designed to maintain calibration stability over time.

Digital models can record torque data for quality control and inspection purposes.

Traceable torque records are essential in regulated industries.

They support compliance audits and maintenance documentation.

applications Where Precision Torque Is Essential

In petrochemical facilities, precise torque prevents flange leaks and unplanned shutdowns.

In power plants, secure bolting protects turbines, pressure vessels, and pipelines.

In aerospace and heavy engineering, controlled torque ensures structural integrity.

Hydraulic torque tools are also suitable for hazardous environments.

Their operation minimizes spark risk compared with impact tools.

A Reliable Choice for Industrial Procurement

For procurement teams, tool reliability and performance consistency are critical factors.

Hydraulic torque wrenches offer predictable results across a wide range of applications.

They reduce rework, minimize joint failures, and improve overall operational safety.

With precision-focused design and industrial-grade durability, solutions from manufacturers such as SAIVS support long-term value for demanding bolting tasks.