Bolting Safety Revolutionized: Washer System Eliminates Hand Injuries

Introduction

Bolting operations are a crucial aspect of maintaining and servicing heavy mining machinery. However, conventional methods utilizing reaction arms and backup wrenches pose a significant risk of hand injuries for operators. These high-powered bolting tools generate immense torque forces, and the reaction arms used to brace them create dangerous pinch points. Backup wrenches, necessary to prevent back-nut rotation, also present pinch hazards during operation. This paper explores the safety concerns associated with conventional bolting techniques and introduces a novel washer system that eliminates these risks entirely.

Safety Concerns in Conventional Bolting

The mining industry prioritizes worker safety, and bolting operations, often overlooked for improvement opportunities, represent a critical area for risk mitigation. Here's a closer look at the safety concerns associated with conventional bolting methods:

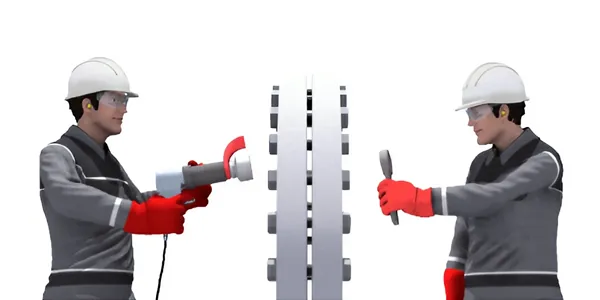

Reaction Arm Pinch Points: Reaction arms, essential for counteracting the high torque generated by power tools, create a significant pinch hazard. Operators may not be aware of the slow turning motion of the reaction arm, leading to injuries when their hands become trapped between the arm and the reaction surface.

Backup Wrench Pinch Points: Backup wrenches, used to prevent back-nut rotation during bolting, can also cause injuries. Slight movements of the wrench during initial positioning can create pinch points between the wrench and the bracing surface, posing a risk to unaware operators.

The impact of these hazards is severe. According to the Occupational Safety and Health Administration (OSHA), hand injuries account for a significant portion of workplace accidents, with heavy industries experiencing even higher rates. These injuries range from broken bones to permanent disabilities and amputations, causing immense physical and financial hardship.

The Washer System: A Safer Bolting Solution

A new washer system offers a groundbreaking approach to bolting safety by fundamentally repositioning the reaction forces. This innovative solution eliminates pinch points entirely, creating a safer work environment for operators.The washer system comprises two key components:

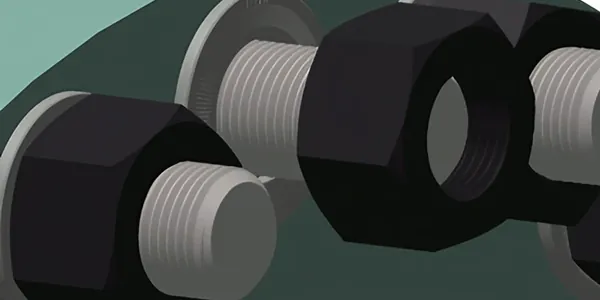

Reaction Washer

This hardened steel washer features a smooth side for contact with the turning element (nut or bolt head), a knurled side to prevent washer rotation against the structural surface, and a reaction surface designed to absorb the torque wrench's reaction forces during tightening. The reaction washer is positioned between the turning element and the structural surface. During the initial tightening (snug-tightening), the washer becomes firmly fixed, preventing rotation. The power torque wrench used with the reaction washer has a dual socket driver with an inner socket for rotating the fastener and an outer socket that engages the reaction surface of the stationary washer. This outer socket acts as a shield, completely eliminating hand exposure to turning elements and reaction forces. With this system, there's no need for a reaction arm, effectively eliminating the associated pinch hazard.

Backup Washer

This circular hardened steel washer is used on the non-turning side of the fastener to prevent back-nut rotation. The washer has knurls on both sides, allowing for a firm fit between the back-nut and the structural surface. Once snug-tightened, the knurls prevent the back-nut from turning, eliminating the requirement for a backup wrench. This not only simplifies the bolting process but also removes a significant safety hazard associated with conventional backup wrenches.

Benefits of the Washer System

The innovative washer system offers numerous advantages over traditional bolting methods:

Enhanced Safety: The primary benefit lies in the complete elimination of pinch points associated with reaction arms and backup wrenches. This significantly reduces the risk of hand injuries for operators.

Improved Efficiency: By eliminating the need for cumbersome reaction arms and backup wrenches, the washer system simplifies the bolting process, leading to increased efficiency.

Reduced Costs: Hand injuries incur substantial costs for businesses, including medical expenses, lost productivity, and potential liability. The washer system's focus on safety can significantly reduce these costs.

Conclusion

The innovative washer system presents a significant advancement in bolting safety for the mining industry. By eliminating pinch points and shielding moving parts, this technology creates a safer work environment for operators. For mining operations involving heavy industrial bolting activities, the washer system offers a compelling solution to mitigate hand injury risks and improve overall safety.