Optimizing Hydraulic Cylinder Performance with SAIVS

Optimizing Hydraulic Cylinder Performance Through Accurate Troubleshooting and SAIVS Component Reliability

Understanding Performance Decline in Hydraulic Cylinders

Hydraulic cylinders and jacks play a critical role in lifting, pushing, and positioning heavy loads across industrial applications. When these units fail or perform below expectations, project efficiency and safety can be compromised. This article focuses on diagnosing performance issues and improving long-term reliability using SAIVS hydraulic components, especially low-profile lock-nut cylinders.

Most Common Symptoms Indicating Cylinder Problems

1. Leakage Around Seals or Fittings

Hydraulic leaks can quickly reduce system pressure and create unsafe operating conditions. In most cases, leakage is caused by worn rod seals, loose fittings, or hose deterioration. SAIVS provides precision-engineered sealing kits designed to restore optimal pressure retention and eliminate fluid loss.

2. Reduced Output Force

When a cylinder fails to generate its rated lifting capacity, the cause may involve low oil volume, internal bypassing, or contamination obstructing valve operation. Testing system pressure with a calibrated gauge is the fastest way to verify whether the pump and cylinder are functioning correctly.

3. Slow or Unstable Cylinder Movement

Slow extension/retraction or inconsistent motion usually points to flow restrictions, misalignment, or valve wear. This is common in heavy-duty applications where cylinders operate under continuous load cycles. SAIVS low-profile cylinders are engineered with hardened components to reduce internal wear and maintain steady performance over extended periods.

Technical Troubleshooting Steps

Step 1: Perform a Full System Inspection

Start by checking hydraulic oil levels, monitoring fluid cleanliness, and ensuring the correct viscosity grade is in use. Dark or milky fluid indicates contamination and must be replaced immediately to prevent internal scoring.

Step 2: Verify Pressure and Flow Conditions

Use a pressure gauge and flow meter to compare actual readings with the cylinder’s rated specifications. If the pump output is normal but motion is weak, internal wear inside the cylinder is the likely cause.

Step 3: Inspect Rod, Piston, and Cylinder Body

Damaged rods, worn piston rings, or barrel scoring can severely affect performance. SAIVS cylinders use precision-ground rods and wear-resistant barrels to minimize these failures, but regular inspections remain essential for preventive maintenance.

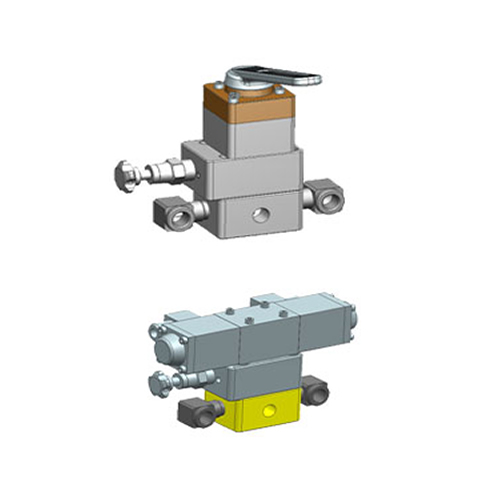

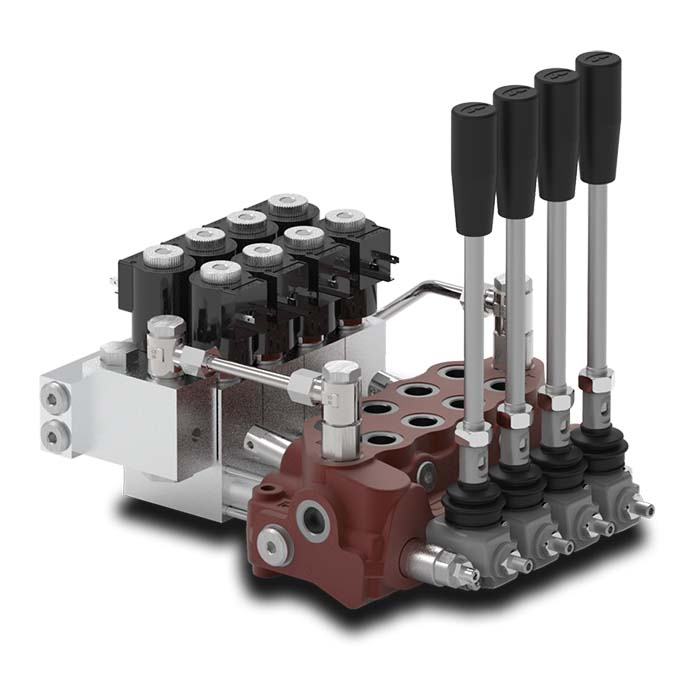

Step 4: Evaluate Valve Performance

Flow control valves and directional valves must operate smoothly. Any sticking or delayed response often leads to jerky or unpredictable cylinder movement.

Why SAIVS Hydraulic Cylinders Offer Greater Reliability

SAIVS low-profile lock-nut cylinders are designed for limited-space lifting and maintenance operations. Their lock-nut mechanism ensures secure load holding, while the compact body allows use in confined industrial environments. High-strength materials, improved seal technologies, and precision machining give SAIVS cylinders superior durability compared with generic alternatives.

Maintenance Practices to Extend Service Life

Routine inspection, correct lubrication, and timely seal replacement significantly reduce downtime. Using genuine SAIVS seal kits ensures compatibility and preserves the cylinder’s original performance rating. Maintaining clean hydraulic oil and following scheduled service intervals also help prevent internal leakage and unpredictable cylinder movement.

Conclusion

Accurate troubleshooting and proper maintenance are essential to maintaining Hydraulic System reliability. Pairing these practices with SAIVS high-quality hydraulic cylinders and accessories ensures consistent performance, higher productivity, and reduced repair costs. For industrial users seeking durable and dependable hydraulic solutions, SAIVS remains a trusted choice.