Hydraulic Tensioning vs Torquing with SAIVS Tools

Introduction — The Importance of Correct Bolt Tightening

In heavy industry, every bolted connection is vital for operational safety and performance.

Improper tightening can lead to leaks, fatigue, or catastrophic joint failure.

Two primary methods dominate the field — hydraulic bolt tensioning and torquing.

This article by SAIVS explains how each process works, compares their benefits, and guides engineers in selecting the most effective tightening method for their specific applications.

Torque vs Tension — The Core Concept

Before discussing tools, it’s important to understand the difference between torque and tension.

Torque is the twisting force applied to turn a nut or bolt head.

Tension is the stretching force that creates the clamp load holding components together.

Although torque is used to create tension, friction between threads and surfaces makes the correlation imprecise — resulting in inconsistent preload unless controlled properly.

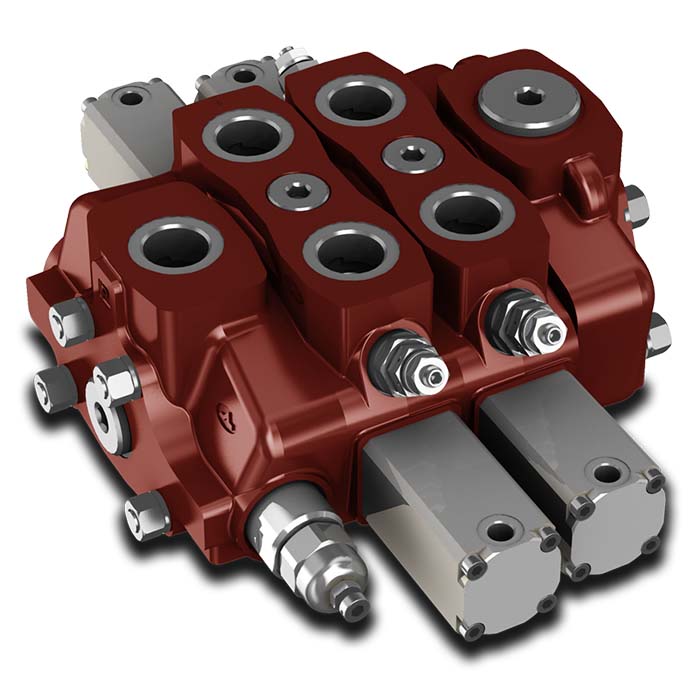

Hydraulic Bolt Tensioning Explained

Hydraulic bolt tensioning is a direct and precise method to achieve accurate bolt preload.

It uses hydraulic pressure to elongate the bolt to a specific tension level.

Once the correct elongation is reached, the nut is tightened to maintain that load as the pressure is released.

Step-by-Step Tensioning Process

1. Place the hydraulic tensioner over the bolt or stud.

2. Apply hydraulic pressure using a SAIVS high-pressure pump.

3. The bolt stretches, achieving the target tension.

4. Tighten the nut to the flange face while maintaining pressure.

5. Release the pressure — the bolt contracts slightly, locking in the desired preload.

Main Advantages of Hydraulic Tensioning

• Exceptional accuracy and repeatability of preload.

• Capability to tension multiple bolts simultaneously, ensuring even load distribution.

• Eliminates torsional stress and thread damage during tightening.

• Ideal for high-pressure, large-diameter, or safety-critical bolted joints.

Limitations of Hydraulic Tensioning

• Higher cost of Hydraulic Systems compared to manual torque wrenches.

• Requires experienced operators and suitable clearance around bolts.

• Not all joints or stud designs are compatible with Hydraulic Tensioners.

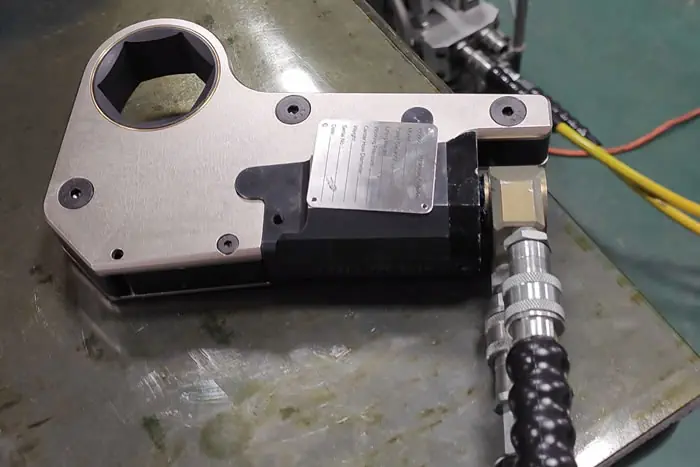

What Is Bolt Torquing?

Bolt torquing uses a torque wrench to rotate the nut, generating tension through friction and thread engagement.

This conventional method remains widely used in industries such as construction, mechanical assembly, and maintenance.

How Torquing Works

When torque is applied, part of the rotational energy overcomes friction between the nut face and the joint surface, and part stretches the bolt.

The resulting axial load provides the clamping force.

The precision of this method depends heavily on thread lubrication, surface condition, and operator skill.

Advantages of Torquing

• Simple to perform, requiring minimal equipment and training.

• Suitable for small and medium bolt sizes.

• Torque wrenches are compact, affordable, and easy to transport.

• Effective for general maintenance and field work.

Disadvantages of Torquing

• Friction variations cause inconsistent bolt preload.

• Possible to over-torque and damage bolts.

• Not suitable for high-pressure or large-diameter bolting applications.

• Accuracy is dependent on regular calibration and controlled conditions.

When Should You Choose Tensioning or Torquing?

Use Torquing When:

• Working on smaller bolts below 1 inch diameter.

• Tightening non-critical joints or performing general maintenance.

• Operating with a limited budget or in areas where portability matters.

• The application does not require extremely tight preload tolerances.

Use Hydraulic Tensioning When:

• Bolting large-diameter studs or flanges in high-pressure systems.

• Precision and even load distribution are essential for joint integrity.

• Simultaneous tightening reduces risk of leakage or flange warping.

• The assembly is mission-critical — such as in oil & gas, wind power, and turbine systems.

industrial applications — How SAIVS Solutions Perform

Oil & Gas: Hydraulic tensioners from SAIVS ensure consistent bolt loads on pipeline and refinery flanges, preventing costly leaks.

Power Generation: Turbine, heat exchanger, and reactor bolting benefit from accurate tensioning for long-term reliability.

Manufacturing: Torquing tools from SAIVS simplify assembly and maintenance on production equipment.

Mining & Construction: SAIVS portable torque wrenches deliver efficiency for equipment repairs in the field.

Choosing the Right Bolting Solution from SAIVS

SAIVS provides both Hydraulic Bolt Tensioners and Hydraulic Torque Wrenches designed for demanding industrial use.

All SAIVS equipment is manufactured for durability, precision, and compliance with international safety standards.

Our engineering experts can evaluate your flange design, bolt size, and preload requirements to recommend the ideal solution — ensuring maximum joint integrity and operator safety.

Conclusion — Achieving Reliable Preload with SAIVS

Both hydraulic bolt tensioning and torquing serve important roles in industrial assembly.

For routine maintenance and smaller fasteners, torquing offers practicality and cost savings.

For high-stress or safety-critical applications, hydraulic tensioning delivers unmatched precision and consistency.

By choosing SAIVS bolting tools, you ensure that every joint is tightened accurately, efficiently, and safely — protecting your operation from downtime and mechanical failure.