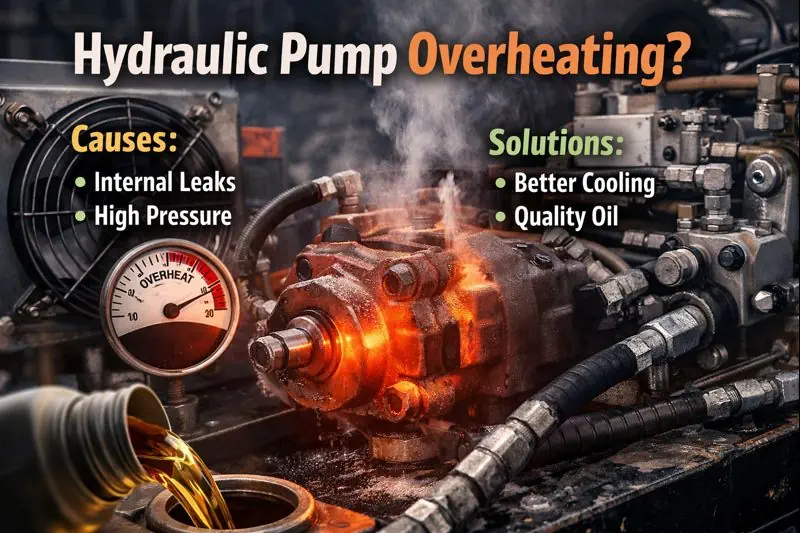

Hydraulic Pump Overheating Causes and Proven Solutions

Hydraulic Pump Overheating Causes and Practical Solutions for Stable System Operation

Hydraulic pump overheating is one of the most common problems in Hydraulic Systems. Excessive temperature not only reduces system efficiency, but also accelerates component wear and oil degradation. Understanding the real causes of overheating and applying targeted solutions is critical for long-term, stable operation.

Why Hydraulic Pump Overheating Should Not Be Ignored

When a hydraulic pump operates beyond its normal temperature range, internal leakage increases. Seals harden faster and lose elasticity. Lubrication performance of hydraulic oil declines sharply.

If overheating is not addressed in time, it may lead to sudden pump failure, system downtime, and costly repairs. For industrial users, this directly affects productivity and operating costs.

Main Causes of Hydraulic Pump Overheating

1. Excessive Internal Leakage

Wear of pump components increases internal clearance. High-pressure oil flows back to the low-pressure area. Energy is converted into heat instead of useful output.

2. Improper Hydraulic Oil Selection

Using oil with incorrect viscosity leads to higher friction losses. Oil that is too thin increases leakage. Oil that is too thick causes flow resistance and heat buildup.

3. System Overload or Long-Term High Pressure

Continuous operation under excessive load forces the pump to work inefficiently. Pressure relief valves may frequently open. Large amounts of energy are released as heat.

4. Poor Heat Dissipation

Blocked coolers or insufficient oil tank capacity reduce heat exchange efficiency. High ambient temperature further worsens cooling performance.

Effective Solutions to Reduce Hydraulic Pump Temperature

Optimize Pump Selection and Matching

Choose a hydraulic pump with appropriate displacement and pressure rating. Avoid operating near the maximum limit for long periods. Correct matching improves efficiency and reduces unnecessary heat generation.

Use High-Quality Hydraulic Oil

Select oil with proper viscosity grade and thermal stability. Regularly monitor oil contamination and oxidation levels. Clean oil ensures better lubrication and heat control.

Improve System Cooling Design

Ensure oil coolers are clean and functioning properly. Increase oil tank volume if needed. Adequate cooling directly lowers operating temperature.

Regular Maintenance Is Essential

Check pump wear, seals, and valves on a scheduled basis. Replace aging components before failure occurs. Preventive maintenance significantly extends pump service life.

Why Choose Reliable Hydraulic Pump Solutions

Stable temperature control is closely related to pump design quality and manufacturing precision. Well-engineered Hydraulic pumps offer higher volumetric efficiency and lower energy loss. This results in reduced heat generation and longer service intervals.

Choosing a trusted hydraulic pump supplier helps minimize overheating risks. It also ensures consistent performance in demanding industrial applications.