Description:

Convenient adjustment mode with supporting gear adjustment mode, suitable for construction environment.

Bolt torque comparison table mode, easy to find the right torque.

Gain adjustment function for quick adjustment of the in-position torque.

Extremely excellent power-to-weight ratio, wider torque range. Lighter and smaller.

Automatic reset anti-seize counteractive arm function for easier operation.

User (operator, administrator) hierarchical function management.

Support third-party intelligent proofreading torque, use software to adjust gain hardware compensation, extend tool life

The torque value of locking and loosening can be recommended according to the strength grade and size of the bolt, and the reference value can be modified to conform to the actual working condition.

The power supply voltage regulator unit and input voltage rectification feedback control function can restrain the fluctuation of power grid input voltage and improve torque precision.

Precision ±5%, repeatability ±2%.

Follow-up monitoring of tightening results (failed, success, uncompleted).

Application:

Chemical plants: Used for tightening valves, pumps, and pressure vessels.

Shipyard maintenance: Used for tightening ship structures and equipment.

Infrastructure development: Used for securing road signs and traffic lights.

Manufacturing assembly lines: Used for torque-controlled assembly of products.

Steel and metal fabrication: Used for tightening steel components and metal structures.

Oil and gas industry: Used for tightening wellheads and pipeline connections.

Image Gallery:

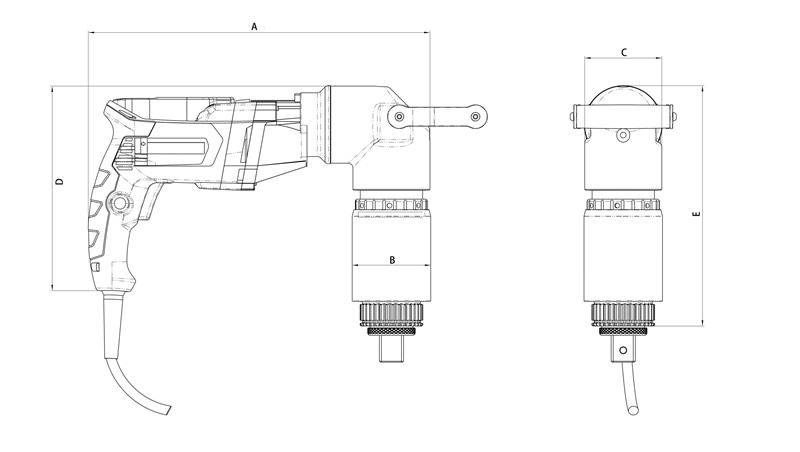

Dimensions:

Series Comparison:

| Model | Square Drive Size | Torque Range(NM) | Speed(RPM) | Weight(KG) | Size A(mm) | Size B(mm) | Size C(mm) | Size D(mm) | Size E(mm) | Noise(db) |

| SM-8AD | 0.75" | 250 | 800 | 10.5 | 7.2 | 363 | 69 | 81 | 216 | 230 | 80 |

| SM-12AD | 0.75"/1" | 350 | 1200 | 8.4 | 7.4 | 363 | 69 | 81 | 216 | 230 | 80 |

| SM-21AD | 1" | 630 | 2100 | 4.8 | 8.4 | 365 | 76 | 81 | 216 | 242 | 80 |

| SM-28AD | 1" | 840 | 2800 | 4.4 | 8.8 | 365 | 78 | 81 | 216 | 256 | 80 |

| SM-40AD | 1"/1.5" | 1200 | 4000 | 3.4 | 9.4 | 366 | 88 | 88 | 216 | 257 | 80 |

| SM-45AD | 1"/1.5" | 1350 | 4500 | 3 | 10.6 | 368 | 86 | 86 | 216 | 282 | 80 |

| SM-60AD | 1.5" | 2000 | 6000 | 2 | 12.2 | 370 | 93 | 93 | 216 | 281 | 80 |

| SM-80AD | 1.5" | 2400 | 8000 | 1.9 | 13.6 | 374 | 102 | 102 | 216 | 291 | 80 |

| SM-100AD | 1.5"/2" | 3000 | 10000 | 1 | 20.5 | 381 | 114 | 114 | 216 | 378 | 80 |

| SM-120AD | 1.5"/2" | 3600 | 12000 | 0.9 | 20.5 | 381 | 114 | 114 | 216 | 378 | 80 |

|

|

|

|

|

|

|

|

|

|

|

|

Product Video:

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our SM-AD Series Elbow CNC Electric Torque Wrench products solutions.

Request a Quote

Product Tags:

SM-AD Series Elbow CNC Electric Torque Wrench High quality hydraulic tools Hydraulic Torque Wrenches Electric Torque Wrench hydraulic bolt torquing machine