6 Key Considerations for Designing an Effective Hydraulic Power Unit

Designing a power unit involves considering several fundamental factors to choose the best approach and the right power unit for the application's needs. Here are seven key considerations:

1. Overall Power and Force Requirements:

The designer needs to determine the power and force requirements of the application, including the size, number of actuators, volumes, and piping runs.

These factors will affect the capacity, power, and force requirements of the power unit.

They also help determine whether a configurable or custom-built unit is needed.

2. Energy Efficiency:

Energy efficiency should be considered in the selection of components and system design.

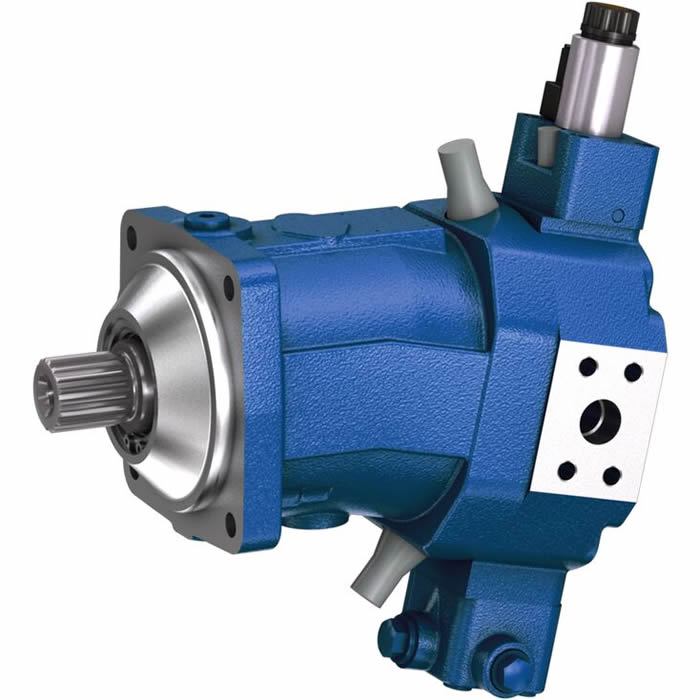

Variable displacement pumps, frequency converters,

or servo-driven variable speed drives may provide energy-saving benefits for applications with varying pressure and flow requirements.

3. Serviceability / Service Life:

The power unit should be designed for easy maintenance and service.

Accessible locations for components such as filter elements and considerations for component replacement should be taken into account.

Good design practices, such as proper piping and clamping, can enhance service life.

4. Noise:

Noise levels may be regulated in certain applications.

Manufacturers may provide noise data for pre-engineered units,

but the installation and operating conditions should also be considered for noise reduction.

5. The Operating Environment and Location:

Factors such as ambient temperature, operating conditions, elevation, and other environmental criteria should be considered.

Specific requirements such as marine certifications or special coatings may be necessary.

The physical location and operating environment can also influence the choice between configurable or custom units.

6. Cost:

Balancing cost with robustness and longevity is crucial, including a comprehensive hydraulic power unit cost comparison.

Opting for low-cost components may seem economical initially but it could lead to higher maintenance and downtime costs over time.

The overall cost assessment of the power unit should encompass ancillary requirements, location considerations,

safety requirements, and a meticulous hydraulic power unit cost comparison to ensure optimal long-term value.

Ensure the longevity and optimal performance of your hydraulic power unit with SAIVS, your trusted partner in Hydraulic Power Unit Maintenance.

We understand that regular maintenance is key to preserving the reliability of your Hydraulic System,

and we are here to support you every step of the way.

Choose SAIVS for Hydraulic Power Unit Maintenance that goes beyond standard service, providing the care and attention your hydraulic power unit

deserves. Trust us to keep your system running smoothly and reliably, ensuring a cost-effective and efficient operation over the long term.