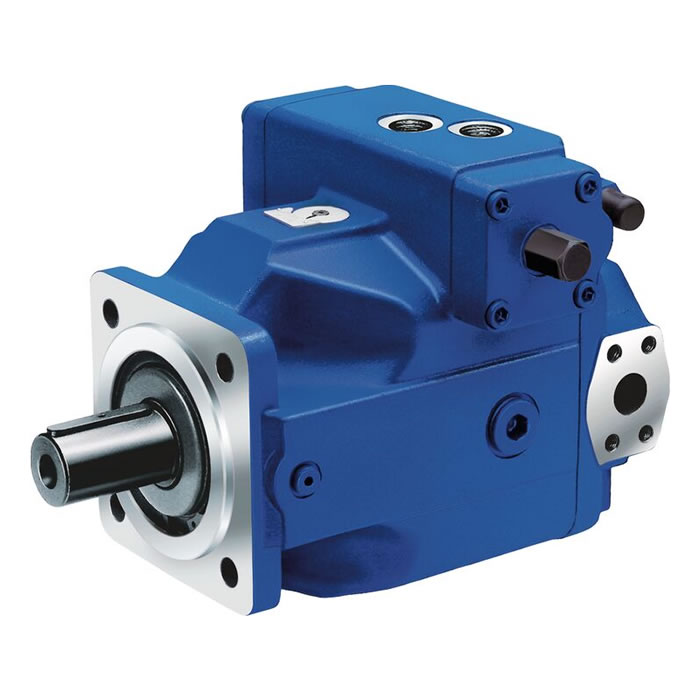

offers original and replacement V10 V20 Hydraulic Vane Pump for our customers. We will save customer costs, increase productivity and profit margins, Welcome to

Get Latest Price now!

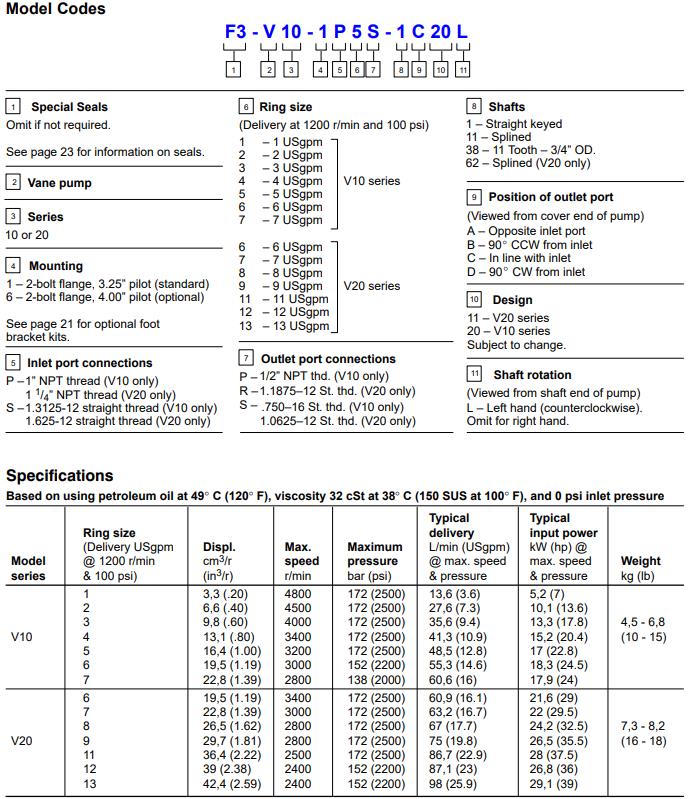

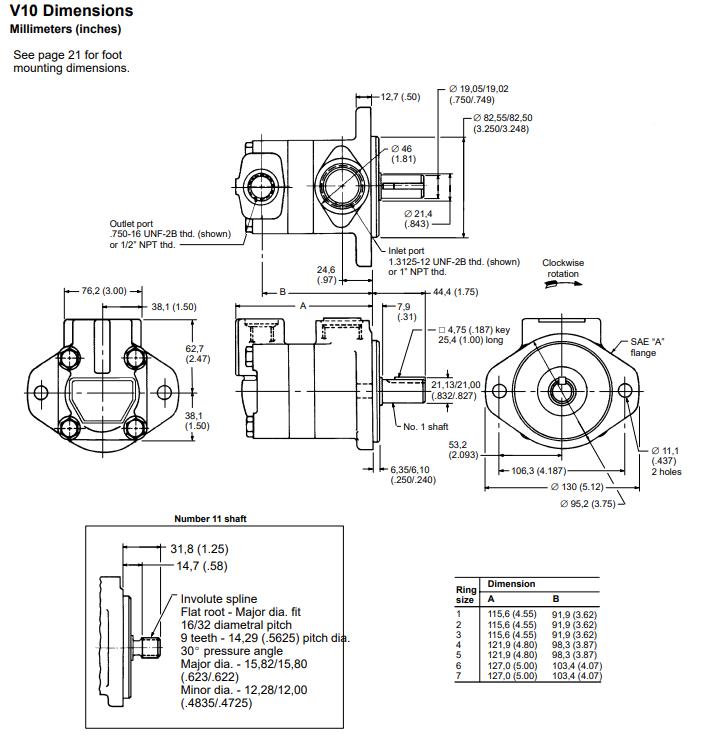

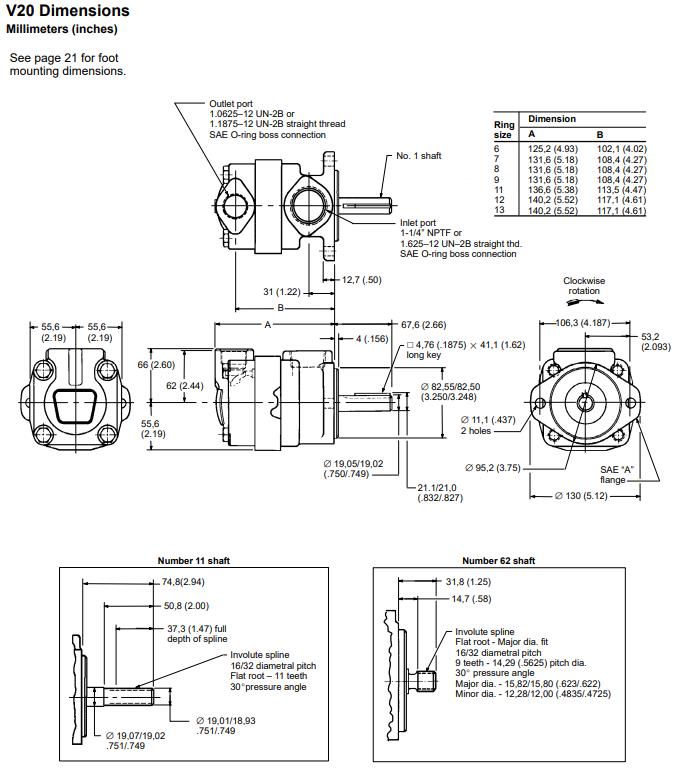

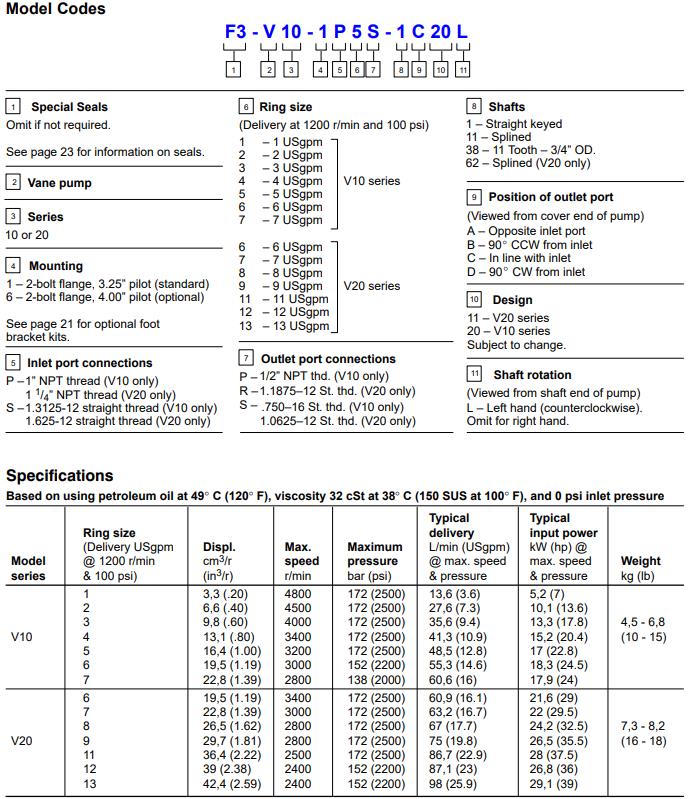

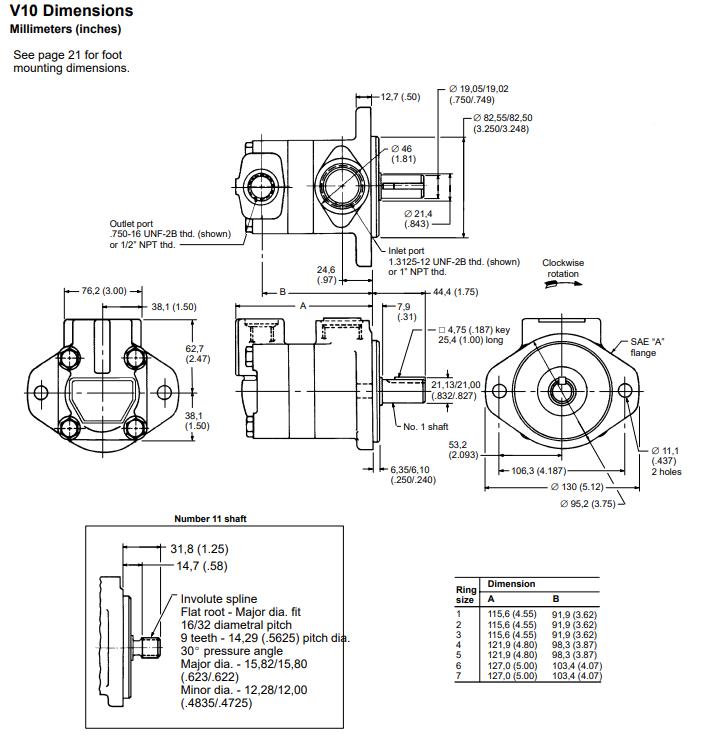

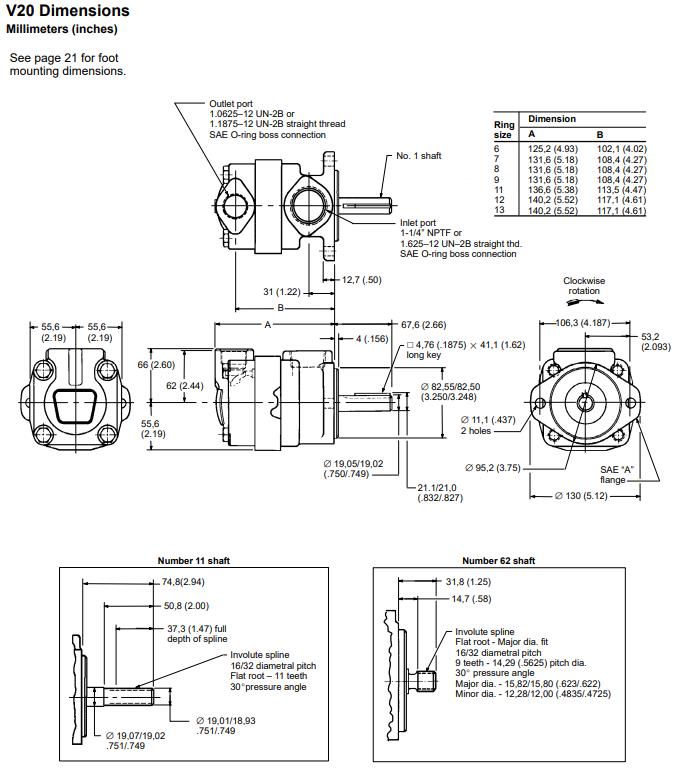

Model Number:V10/V20

Pressure:High Pressure

Structure:Vane Pump

Max pressure(MPa):17.2MPa-19MPa

Usage:Oil

Power:Hydraulic

Application:Other

Fuel:hydrauilc oil

Theory:Rotary Pump

Standard or Nonstandard:Standard

Warranty:1 Year

Place of Origin:Zhejiang, China

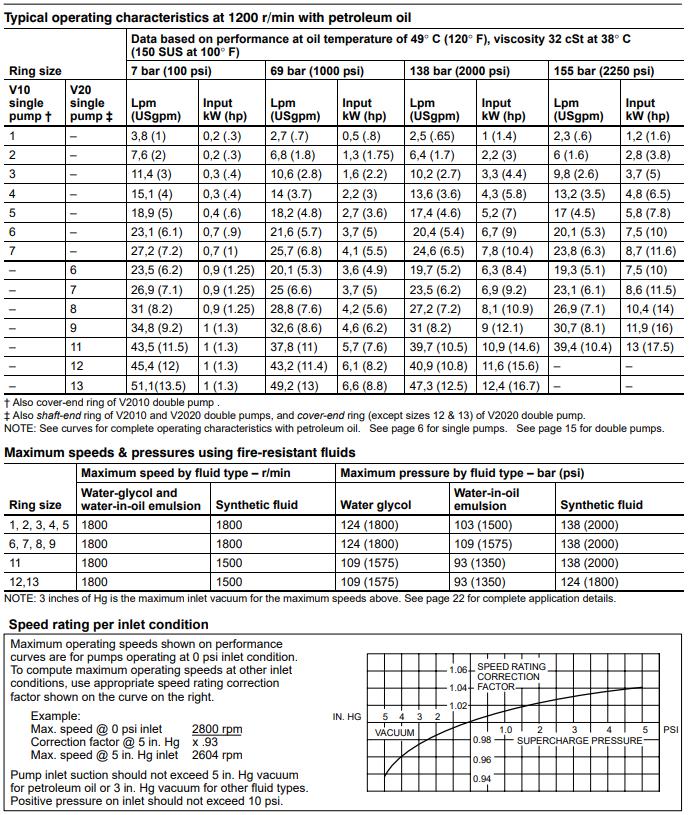

Eaton Vickers V10 V20 Series Vane Pumps

1.In installation, the tolerance of concentricity between shaft of pump and motor must be less than 0.10mm(TIR) by using the flexible coupling; The pump shaft shall not bear the radial and axial load ; The carrier must be firm with good rigidity and can fully absorb vibrations.

2. Fix pipes, especially inlet pipes in accordance with the size of port and assemble safety relief valves in the system. The regulating pressure of the safety valve shall not be greater than the maximum pressure of the pump; Inlet pipes must be strictly sealed with no leakage; The fuel tank shall be equipped with a diaphragm to separate the bubbles and dirt from the oil; The oil return nozzle should be lower the fluid surface, the minimum depth of 50mm, even in a low, too, when the permissible level of to avoid the formation of bubbles .

3.Set the suction pressure at pump inlet port : Oil hydraulic oil is + 35 ~ -16.7KPa. The hydraulic oil of water - glycol and phosphate ester was + 35 ~ -10.1KPa.

4.In case where the pump is installed on the tank or at the position higher than the tank top cover, the height of the suction port of the pump should be less than 500mm.

5.Oil should be kept clean, pipes and tanks must be thoroughly cleaned; Precise filters should be assembled with the advised precision of 25μm in the system, the cleanness level of oil should be within NSA12. Fix the sufficient-volume filter (the rated flow rate should be greater than twice the pump flow )at the inlet of the pump 50mm above the bottom of the tank, with the suggested precision of 100μm(150 mesh).

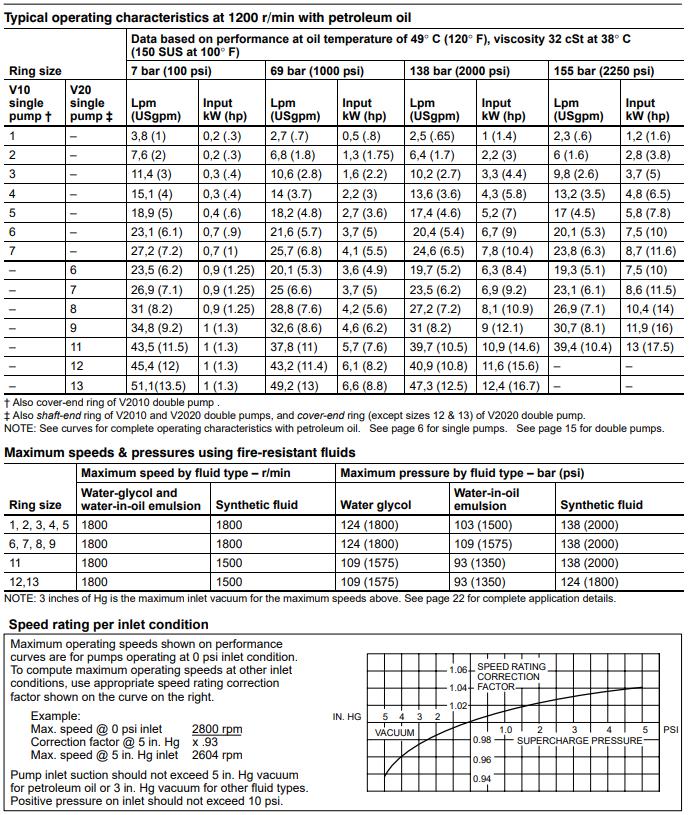

6.Pumps can be used with anti-wear hydraulic oil, or automotive type crankcase oil (designations SC, SD, SE, SF, or SG) per SAE J183 JUN89. Fire-resistant fluids can also be used, but may require the use of special seals. The viscosity range of petroleum oil, with the pump running, should be 13-54 cSt. The oil viscosity at 38 ℃ should be 32-48cSt. Fire-resistant fluids should have a viscosity as close as possible to that of petroleum oil as described above. A maximum specific gravity of 1.3 is suggested for fire resistant fluids. An operating temperature of 49 ℃ is recommended. The maximum temperature for oil should be 65 ℃ , and the maximum for water-containing fluids should be 54 ℃ .

7.Seals nitrile: Seals are standard and are suitable for use with petroleum, water-glycol, water-in-oil emulsion, polyol ester, and high-water-base fluids. Phosphate ester fluids require the use of fluorocarbon seals, which are identified in model codes as an “F-” prefix.

8.Check the inlet, outlet and direction of rotation before starting the pump. Turn the shaft of pump evenly and nimbly by hand after fixing the pump. Fill the pump with system fluid through the uppermost port. The housing must be kept full at all times to provide internal lubrication. At initial startup, it may be necessary to bleed air from the pump outlet to permit priming and reduce noise. Bleed by loosening an outlet connection until a solid stream of fluid appears.

9. At startup, If the oil viscosity is higher than the suitable viscosity ,the pressure should be limited to 50% or less of their respective rated values until the system has warmed up.

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our V10 V20 Hydraulic Vane Pump products solutions.

Request a Quote

Tags: V10 V20 Hydraulic Vane Pump Vane Pump