common faults of hydraulic bolts stretcher

Common Faults of Hydraulic Bolts Stretcher

SAIVS has been producing and selling hydraulic bolts stretcher for many years, and has rich experience in handling the use failure of Hydraulic Bolt Tensioners. The summary is as follows:

1. Hydraulic bolt tensioner leaks oil

The main reason is that the upper and lower sealing rings are worn and aged, the vent screw is not tightened or damaged, and the lift of the hydraulic stretcher exceeds the maximum lifting height during the working process.

Measures to be taken: replace the sealing ring, tighten or replace the vent screw, and disassemble the hydraulic stretcher after pressure relief.

Precautions: when using the hydraulic stretcher, do a good job of personal protection. Pay close attention to all the hydraulic stretchers when pumping. If any oil leakage is found, stop the pump oil in time and drain the oil pressure.

2. The hydraulic stretcher cannot be removed

Main reasons: when removing the nut, the hydraulic stretcher is not loosened after installation, or the nut is not loosened enough, too much of which touches the bottom plane of the sliding piston.

Measures to be taken: when removing the nut, the screw loose is not the same according to the large lifting height of the hydraulic stretcher, and the operation shall be in strict accordance with the instructions. When loosening the nut, the upper surface of the nut shall not touch the bottom of the sliding piston.

Note: when removing the nut, observe the hydraulic stretcher during the pump pressure to prevent the hydraulic stretcher from rotating when the high-pressure oil pipe is filled with oil.

3. The sliding piston is stuck

Main reasons: rough contact surface between sliding piston and oil cylinder, hard particles and other wastes in the sealing chamber.

Measures to be taken: disassemble the hydraulic stretcher, polish the contact surface, replace the damaged sealing ring and thoroughly clean the inside of the sealing chamber.

Precautions: the hydraulic stretcher shall be cleaned after use, and the quick connector shall be covered with a cover to prevent garbage from entering, and stored in the special tool cabinet.

4. Oil leakage of quick connector

Main cause: the quick connector is not installed in place, and the internal parts of the quick connector are damaged.

Action: install the quick connect fitting correctly

Note: during the process of pump pressure, the staff should keep away from the quick connector to prevent injury after the quick connector is loose.

5. Nut stuck

Main cause: the external thread on the bolt is bruised. When using the hydraulic stretcher to remove the nut, the nut is loosened too much or too little.

Measures to be taken: repair the damaged thread and loosen the nut no more than 1 turn.

Note: after the nut is installed, install the upper protective cover.

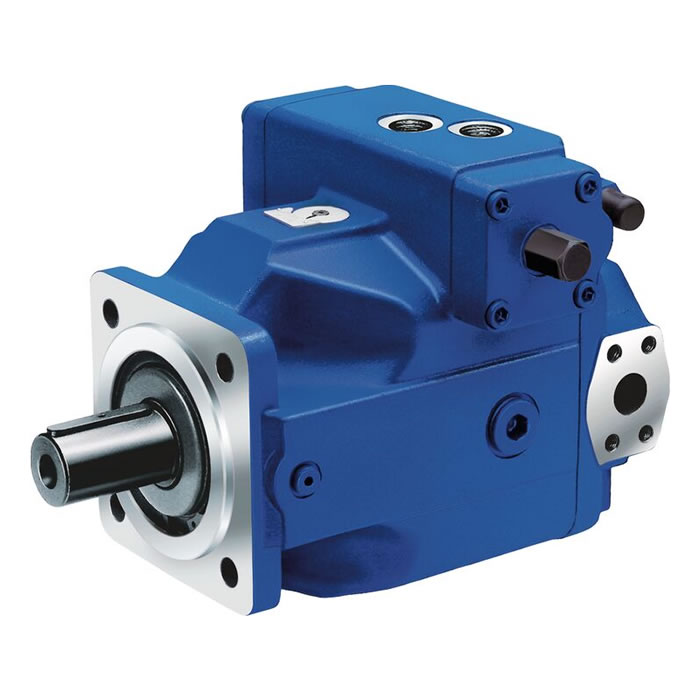

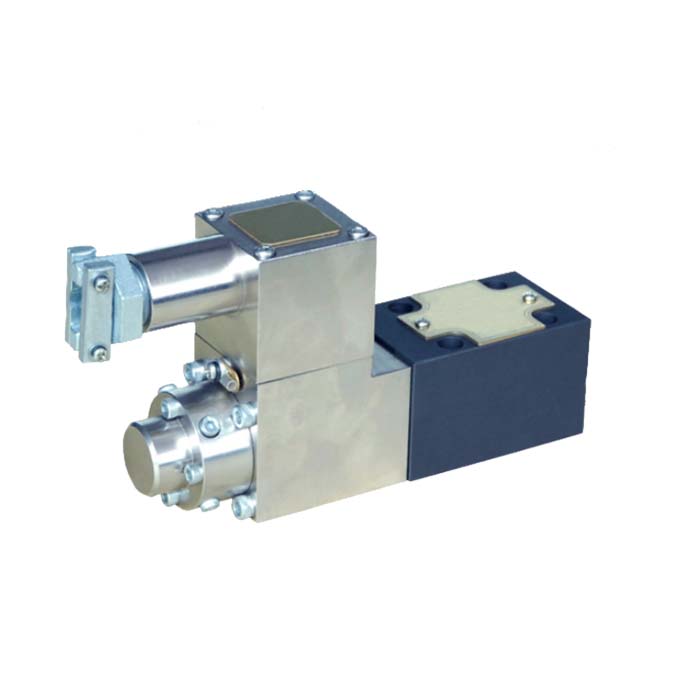

Hydraulic bolt stretcher, Hydraulic Bolt Tensioner