Mastering Hydraulic Torque Wrench Operation

Optimal Hydraulic Torque Wrench Operation: A Comprehensive Guide

Hydraulic torque wrenches are indispensable tools in industrial manufacturing. Renowned for their versatile functionality and the powerful torque they apply to large bolt heads, they are critical for countless industrial applications.

However, like any precision tool, proper operation is key to maximizing efficiency, ensuring safety, and prolonging the life of the equipment and the components it fastens.

This technical guide outlines the correct procedures for operating a hydraulic torque wrench, emphasizing three crucial stages: assembly, setting, and application.

The Importance of Correct Assembly

The assembly phase of a hydraulic torque wrench is paramount, as incorrect setup can lead to inefficiencies or even damage.

For drive-type hydraulic torque wrenches, it's essential to first confirm that the power pack is securely connected to the wrench's other end.

Ensure that all connectors are tightly secured.

Furthermore, verify that all three components of the hydraulic torque wrench assembly are safely and correctly linked together.

A meticulous assembly process lays the groundwork for safe and effective operation.

Precision in Setting the Torque Wrench

Accurate torque settings are fundamental to achieving the desired fastening results without over-stressing bolts or nuts.

Typically, hydraulic torque wrenches come with a torque chart that guides the adjustment and setting process.

If your specific wrench lacks an explicit setting recommendation, it's advisable to begin with the lowest setting.

Gradually increase the torque while operating the wrench.

A critical caution during this process is to avoid over-tightening any bolts or nuts, especially those that are being subjected to initial torquing.

Excessive force can lead to significant damage, including stripping threads or even breaking components, which can incur costly repairs and project delays.

Effective Application of the Hydraulic Torque Wrench

The application stage requires careful attention to detail to ensure optimal performance and prevent errors.

When connecting the hose and nut, it is crucial to first check that the seal ring of the drive-type hydraulic torque wrench is correctly aligned.

This seemingly minor detail is incredibly important.

Failure to ensure proper alignment beforehand will significantly impede work efficiency during subsequent operations, potentially leading to mistakes and damage to the equipment or the workpiece.

Generally, achieving correct alignment is straightforward: simply press the two pipes together until they seat properly.

Next, adjust the pressure regulating valve to release pressure, preparing the hydraulic torque wrench for its final adjustments.

Once these preparatory steps are complete, you can begin operating the wrench.

When the wrench automatically stops, this indicates that the desired torque has been reached.

At this point, you can release the torque wrench and then safely remove it from the fastener.

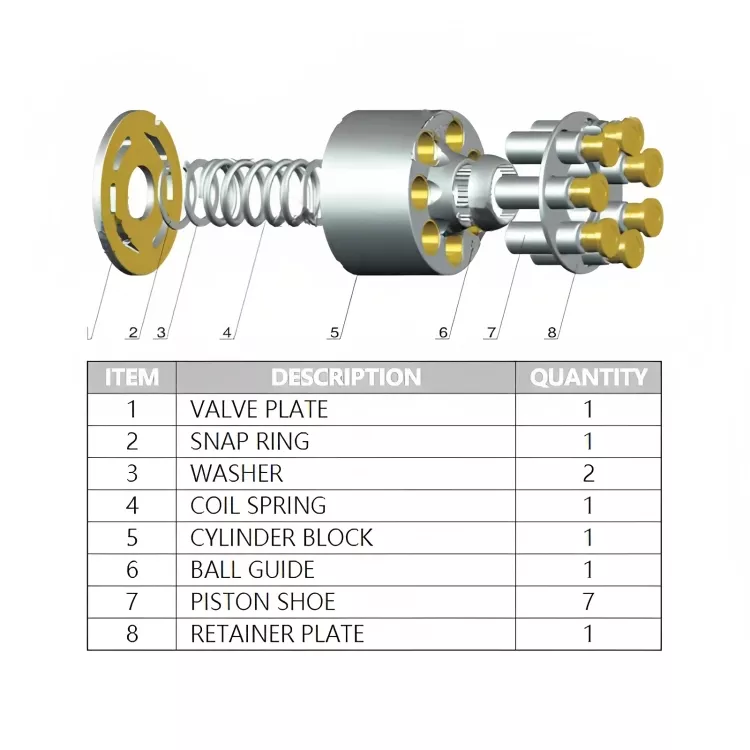

AVANTI 0.7-35, 153-43156 NM, Square Drive Hydraulic Torque Wrench

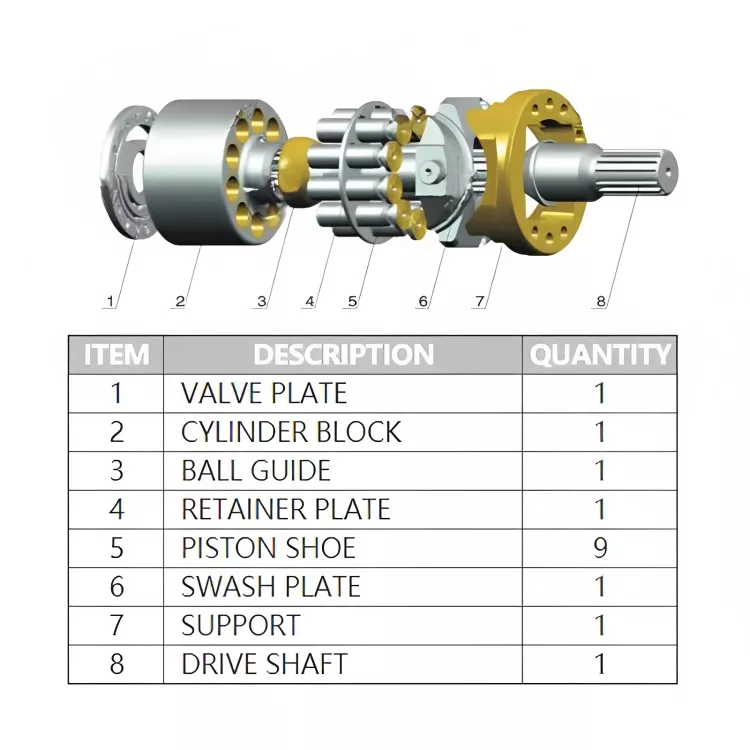

Black,SBT Series Square Drive Hydraulic Torque Wrench

Maximizing Performance and Safety with Our Hydraulic Torque Wrenches

Understanding and adhering to these precise operational guidelines for hydraulic torque wrenches is vital for any industrial application.

Our range of hydraulic torque wrenches is engineered for durability, precision, and ease of use, making them an invaluable asset for your industrial needs.

By following these best practices, you can ensure the longevity of your equipment, enhance operational safety, and achieve consistently accurate fastening results.

Should you encounter any challenges during the actual operation process, always consult the corresponding user manual for detailed guidance and troubleshooting.

Invest in our high-quality hydraulic torque wrenches today to experience unparalleled performance and reliability in your industrial fastening tasks.

For more information on our robust and precise hydraulic torque wrenches, or to discuss your specific application needs, please contact our expert team.

We are dedicated to providing superior tools that drive efficiency and success in your operations.