Instructions for disassembly and assembly of hydraulic motors

The clearance of each moving pair of the motors delivered by talems hydraulic has been matched, and users are not allowed to replace parts at will. Under normal circumstances, do not disassemble the motor at will. Only in case of serious failure can the motor be disassembled and inspected with the consent of our company.

(1) Preparation before disassembly

1 remove the oil drain plug and drain the oil in the motor housing.

2 loosen the 5 screws on the oil pan and remove the oil pan.

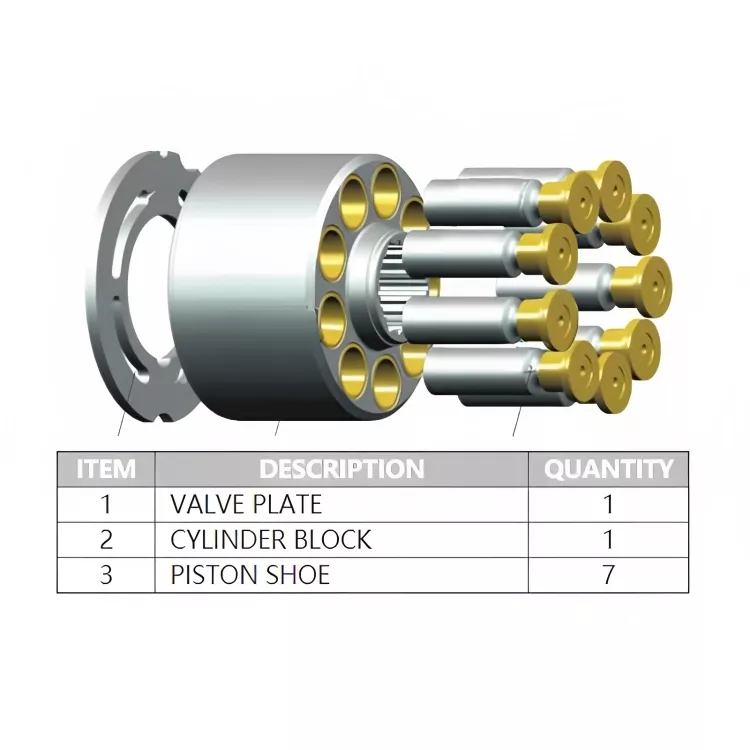

3 take out the oil distribution plate, locating ring, cushion block, cylindrical pin and double headed key.

Note: in order to prevent the change of rotation direction after reassembly, the end face of the output shaft and the surface of the oil distribution plate must be marked in the same direction.

(2) Disassembly and assembly sequence

1 remove the cover, screw the clean screw into the central screw hole of the crankshaft, and lift out the crankshaft.

2 remove the snap ring on the connecting rod.

3 take out the assembly of the connecting rod of the plunger body and make corresponding marks one by one, so that the original clearance can be guaranteed during reassembly. Generally, the user can check and repair the plunger body and connecting rod after disassembling it here. If necessary, the assembly of the plunger body and connecting rod can be disassembled: loosen the spring retaining ring for the hole, take out the retaining ring, and the plunger body and connecting rod can be separated.

4 assemble according to the reverse procedure above, and pay attention to ensuring the axial clearance of the bearing.

5 all parts must be cleaned before assembly to avoid scratching or bumping any working surface.

6 if only the sand hole of the plunger sleeve leaks oil or the joint surface of the plunger sleeve and the shell leaks oil, loosen the screw on the plunger sleeve, remove the plunger sleeve, and replace the plunger sleeve or "O" ring.

Easy problems of Hydraulic Motor, cause analysis and troubleshooting

Serial number:

Fault phenomenon

Cause analysis

Exclusion method:

The rotation is opposite to the predetermined direction

Reverse installation of oil distribution plate

Remove the oil distribution plate, take out the oil distribution plate, rotate it 180 degrees, and then reinstall it.

1. Faults in other parts of the system

Check the system and eliminate it.

The rotation speed decreases and the operation is abnormal, and the output torque decreases.

2. Serious external leakage of motor

1. Check the contact surface between the oil pan and the housing; 2. Check the seals between the parts; 3. Check the viscosity of the hydraulic oil and the working oil temperature; 4. Check the wear of the parts of the moving pair

3. Large leakage in the motor

1. Check the wear of the sealing ring on the oil distribution plate 2. Check the wear of the oil passage plate and check whether the two oil chamber channels at the inlet and outlet of the casting are connected.

The motor does not rotate and the pressure does not go up

1. Faults of other parts of the system 2. Broken double headed key

1. Check the system and eliminate it. 2. Remove the oil pan and oil distribution pan and replace the parts.

The motor does not rotate and the pressure increases

1. Some moving pairs inside the motor bite each other; 2. The load exceeds the set value

Disassemble for inspection and replace parts.

Oil leakage of plunger sleeve or oil pan

Sand hole of casting

Replace casting

Other oil leaks from the contact surface with the housing and the end surface of the output shaft

The rubber sealing ring is damaged or aged

Replace rubber sealing ring

The oil seal is damaged or its spring falls off and is aged, the bearing is worn, and the shaft runout is large

1. Replace the oil seal 2. Adjust the clearance or replace the bearing

Abnormal noise

1. The connecting rod and the bearing sleeve bite or damage 2. The snap ring is broken and the bearing bites. 3. Coupling misalignment 4. External vibration 5. Noise of other Hydraulic Systems

1. Replace the parts, check the bearing on the thrust seat for damage and clearance, and correct. 2. Check and correct the coaxiality of the coupling connected to the motor. 3. Correct coaxiality 4. Take anti vibration measures 5. Check the system and eliminate it.

Temperature rise too fast

1. Insufficient system cooling 2. Serious wear of main parts

Check and improve. Same as troubleshooting in fault 4

Fault causes and troubleshooting instructions for ordering:

1 the user can select motors of different specifications according to the working requirements of the host. When ordering, please indicate the product model, quantity, delivery date and destination. You can send a letter or fax.

2 if there are special requirements for installation and connection dimensions, please contact our company to handle relevant procedures when ordering.