How to maximize the service life of hydraulic valves

Maximizing Hydraulic valve Lifespan: Best Practices and Performance Optimization

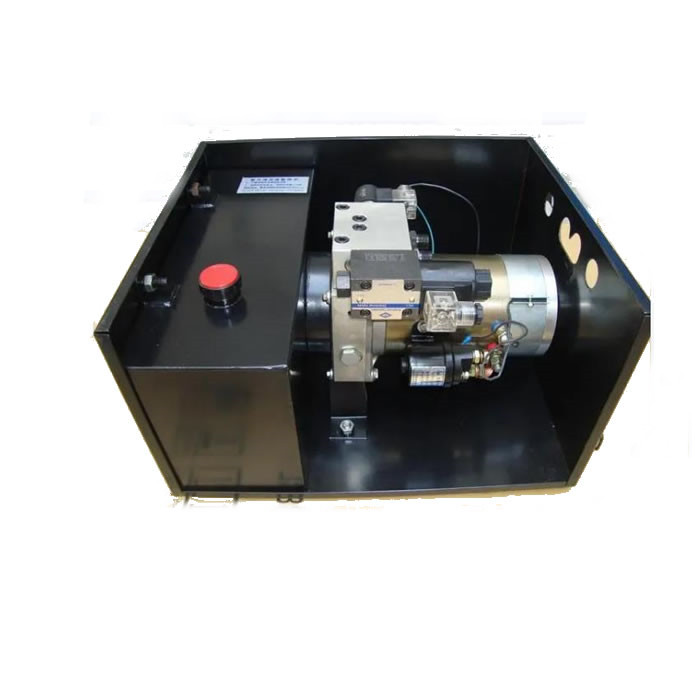

Hydraulic valves are essential components in Hydraulic Systems, playing a crucial role in controlling the flow and pressure of fluids.

However, the lifespan and performance of hydraulic valves are influenced not only by their manufacturing quality but also by their proper usage.

Correct operation can significantly extend the valve’s lifespan, while improper use may lead to premature failure.

This article explores the importance of correct valve operation and how users can optimize the performance of hydraulic valves

by understanding their pressure-flow characteristics and adhering to best practices in their usage.

Understanding Hydraulic Valve Lifespan

The longevity of a hydraulic valve is largely determined by its quality and how it is used within a system.

While premium valves are built to withstand tough operating conditions, misuse or improper installation can dramatically shorten their lifespan.

Common issues such as operating valves at excessive pressures, improper flow settings, or incorrect fluid types can cause internal wear, leading to failure.

To maximize the life of a hydraulic valve, operators must adhere to the manufacturer's guidelines regarding pressure limits, flow rates, and fluid types.

Regular maintenance, such as checking for leaks, inspecting seals, and cleaning filters, is equally crucial to ensure long-term functionality.

Pressure-Flow Characteristics: Key Performance Indicators

The pressure-flow characteristics of hydraulic valves are a critical factor in assessing their performance.

These characteristics define how the valve operates under different flow rates and pressures.

By analyzing these properties, engineers can gauge the efficiency and effectiveness of a hydraulic valve in various applications.

A key goal when selecting hydraulic valves is to minimize pressure loss at a given flow rate.

Lower pressure losses indicate better valve performance, as less energy is wasted in the system.

Valves that can handle higher flow rates while maintaining low pressure loss are typically more efficient and durable.

When comparing different valves, a valve with lower pressure loss at the same flow rate will outperform others, offering improved system efficiency.

Common Issues with Hydraulic Valve Installation

Improper Oil Tank Connections:Hydraulic valves with oil drain ports must be correctly connected to the oil tank, not to the system’s main return line.

If a valve like a pressure relief valve is connected to the return line, fluctuations in flow rate can cause inconsistent pressure, resulting in unstable valve output. This can lead to system inefficiency and damage to other components.

It is crucial to ensure proper routing of the return oil to avoid these complications.

Electric-Hydraulic directional valves with No Preload:Some electric-hydraulic directional valves are designed to control the direction of fluid flow but require preloading to function correctly.

If the valve does not have a pre-load or back-Pressure Valve in the return line, it will fail to operate properly.

Adding a preload valve to the P-port or a back-pressure valve to the return line ensures stable operation and prevents malfunction.

Best Practices for Optimal Hydraulic Valve Performance

To ensure optimal performance and extend the lifespan of hydraulic valves, users should adopt the following best practices:

- Proper System Setup: Follow installation guidelines carefully to avoid incorrect connections, especially for oil drain and return lines.

- Adherence to Flow and Pressure Limits: Ensure that the hydraulic valve operates within the specified flow and pressure range.

- Routine Maintenance: Regular inspections, cleaning, and servicing of hydraulic valves prevent wear and tear from affecting their performance.

In conclusion, while hydraulic valves are vital components for fluid control in machinery, ensuring their longevity and optimal performance relies on correct installation, operation, and maintenance. Understanding pressure-flow characteristics, avoiding improper connections, and using valves within their intended operational limits are key to achieving the best performance and extending their lifespan.

Conclusion: Achieving Efficiency Through Proper Use

Proper use of hydraulic valves is essential not only for their longevity but also for maximizing system efficiency.

By paying attention to the pressure-flow characteristics and adhering to best practices in installation and operation,

users can optimize their hydraulic systems and reduce the risk of costly failures.

Following these principles will help ensure the hydraulic valves continue to perform at their peak for years.