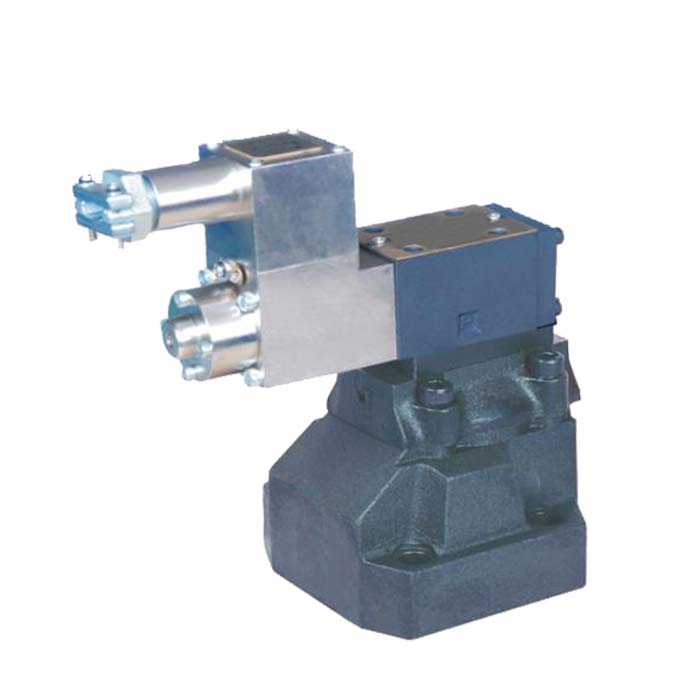

How to maintain the hydraulic power unit

When a hydraulic power unit breaks down, only a trained professional should conduct repairs.

However, routine preventative maintenance is not quite so demanding a task. As long as you follow

manufacturer's instructions for maintenance, you should be able to conduct preventative maintenance

on your own without risking the safety of those using the power unit.

Lubricating electric motors

Proper lubrication is essential for maintaining the performance and longevity of electric motors.

To ensure effective lubrication, it is recommended to follow the manufacturer's guidelines provided in

the motor's manual or by contacting the manufacturer directly. These guidelines will outline the specific

lubrication requirements and frequency for your particular motor model. Adhering to the recommended

lubrication practices is crucial to keep the motor in optimal condition.

Cleaning or replacing filters

The power unit of your electric motor may be equipped with a filter that indicates

when it requires cleaning or replacement. It is important to check this indicator immediately

after starting up the system to address any maintenance needs before operating the power unit.

If your power unit does not have an indicator, refer to its manual to determine how often you should

clean or replace the filter. When replacing a filter, ensure that you use a similar type as specified

by the manufacturer. If cleaning is required, carefully follow the provided instructions

to thoroughly remove all contaminants before reinstalling.

Cleaning suction strainers

Suction strainers in your machine typically require cleaning after approximately 10 hours of initial use

and then every 100 hours thereafter. However, it is important to consult

your specific manufacturer's guidelines for precise cleaning intervals.

Maintaining oil level in reservoirs

Regularly checking and maintaining proper oil levels in reservoirs are crucial for optimal motor performance.

Periodically inspecting oil levels, especially during initial usage of the power unit, ensures they do not

fall below recommended thresholds. Ideally, check reservoir levels after every 100 hours of operation.

Changing the oil

The oil in your hydraulic power unit should be changed based on manufacturer requirements.

Typically, oil changes are needed somewhere between 1,000 and 2,000 hours of use; however,

this can vary depending on factors such as environmental conditions and application demands placed on the power unit.

Checking the oil

It is important to monitor oil temperature during operation to ensure it does not run too hot.

Signs that indicate overheating include significantly darker color compared to fresh oil and a burnt smell.