How to Troubleshoot and Fix Slow Hydraulic Motor Speed

Introduction

If you’ve noticed that your Hydraulic Motor is running slower than usual, it can be frustrating and may even disrupt your workflow.

Hydraulic Motors are essential components in many machines, and their performance directly impacts productivity.

A slow-running hydraulic motor can be caused by several factors, ranging from simple issues like low fluid levels to more complex problems like internal wear or system inefficiencies. In this article, we’ll walk you through some practical steps to diagnose and fix the issue, so you can get your hydraulic motor back up to speed.

Step 1: Check the Hydraulic Fluid Level and Quality

The first thing you should do is check the hydraulic fluid level in the reservoir.

Low fluid levels can cause the motor to run slower because there isn’t enough fluid to generate the necessary pressure.

If the fluid level is low, top it up to the recommended level. But don’t stop there—also inspect the quality of the fluid.

Dirty or contaminated fluid can clog filters, valves, and other components, reducing the motor’s efficiency.

If the fluid looks murky or has debris in it, it’s time to drain and replace it with fresh, clean hydraulic oil.

Step 2: Inspect the Hydraulic Filters

Clogged or dirty filters are a common culprit behind slow hydraulic motor speeds.

Filters are designed to trap contaminants, but over time, they can become blocked, restricting fluid flow and reducing system pressure.

Locate the filters in your Hydraulic System and check them for dirt or damage.

If they’re clogged, replace them with new ones.

Regularly changing filters is a simple yet effective way to maintain optimal hydraulic motor performance.

Step 3: Examine the Pump and Pressure Settings

The hydraulic pump is the heart of the system, and if it’s not functioning properly, the motor won’t get the power it needs to run at full speed.

Check the pump for signs of wear or damage, such as leaks or unusual noises. Also, verify that the pressure settings are correct.

If the pressure is too low, the motor won’t receive enough force to operate efficiently.

Use a pressure gauge to measure the system pressure and adjust it according to the manufacturer’s specifications.

Step 4: Look for Internal Leaks or Wear

Internal leaks within the hydraulic motor or system can also cause a drop in speed.

These leaks can occur in seals, valves, or other components, allowing fluid to escape and reducing the pressure available to the motor.

Inspect the motor and surrounding components for signs of leaks, such as puddles of fluid or worn-out seals.

If you find any issues, replace the damaged parts promptly.

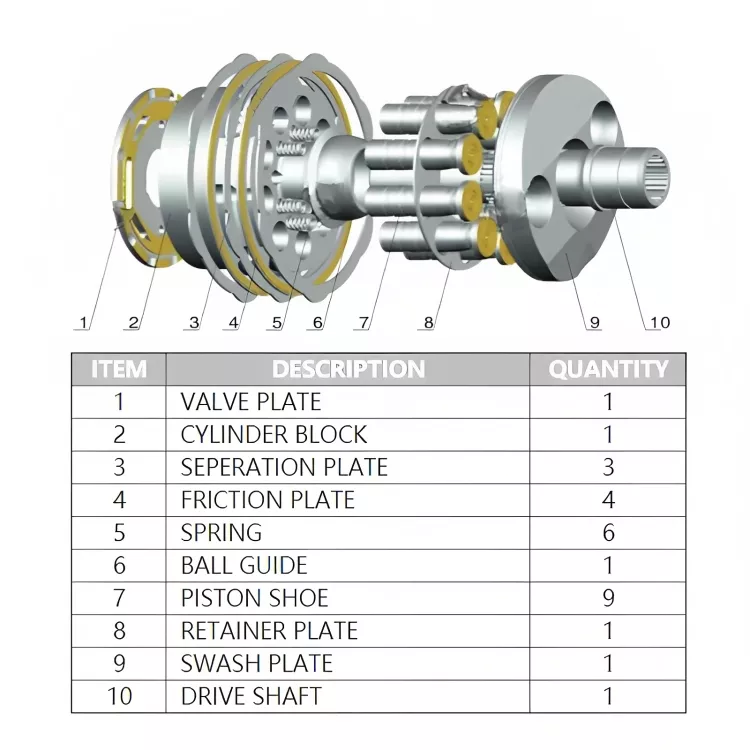

Additionally, internal wear in the motor itself, such as worn vanes or gears, can reduce its efficiency.

In such cases, you may need to rebuild or replace the motor.

Step 5: Check for Air in the System

Air trapped in the hydraulic system can cause the motor to run sluggishly.

This is often accompanied by a spongy feel in the controls or unusual noises.

To remove air from the system, follow the manufacturer’s bleeding procedure.

This usually involves running the motor at low speed while opening valves or fittings to release trapped air.

Once the air is purged, the motor should run more smoothly and at the correct speed.

Step 6: Evaluate the Load and System Design

Sometimes, the issue isn’t with the motor itself but with the load it’s handling or the overall system design.

If the motor is under excessive load, it may struggle to maintain speed.

Check if the load is within the motor’s rated capacity.

Additionally, review the system design to ensure it’s optimized for the motor’s performance.

Inefficient piping, undersized components, or improper valve settings can all contribute to slow motor speeds.

Conclusion

A slow hydraulic motor doesn’t have to bring your operations to a halt.

By following these steps—checking fluid levels, inspecting filters, examining the pump, looking for leaks, purging air, and evaluating the load—you can identify and resolve the issue efficiently.

Regular maintenance and timely troubleshooting are key to keeping your hydraulic motor running at peak performance.

If the problem persists after these checks, it may be time to consult a professional for a more in-depth diagnosis.