High-Performance Hydraulic Flange Spreaders for Safer Industrial Maintenance

High-Performance Flange Spreader Systems for Modern Industrial Operations

In today’s industrial maintenance environment, minimizing downtime while maximizing safety has become a core objective.

Flange separation, although common, carries inherent risks if performed with outdated or inefficient tools.

SAIVS delivers advanced flange spreader solutions engineered to meet the evolving demands of oil & gas, petrochemical, power generation, and heavy industrial sectors.

Redefining Flange Separation with Engineering Precision

Traditional mechanical flange spreaders often depend on excessive manual force, increasing the likelihood of uneven separation and workplace injuries.

SAIVS Hydraulic Flange Spreaders introduce controlled force application, allowing operators to perform precise separation without compromising flange integrity.

By utilizing hydraulic pressure, these tools generate up to 16 tons of spreading force per unit, or 32 tons when paired, ensuring stable and predictable results.

Hydraulic Technology That Enhances Safety

Hydraulic operation significantly reduces the physical strain placed on technicians.

More importantly, it provides smooth, incremental force application, preventing sudden movements that may damage equipment or endanger personnel.

This makes SAIVS flange spreaders especially suitable for high-pressure piping systems and critical process connections.

Operational Benefits of Hydraulic Flange Spreaders

• Accurate force control improves alignment and protects flange faces.

• Reduced maintenance risk lowers the chance of gasket and bolt damage.

• Improved work efficiency allows faster completion of routine service tasks.

Integral Pump Flange Spreaders: Simplified Workflow

One of the most practical innovations in flange spreader design is the integral hydraulic pump.

Instead of relying on external pumps and hoses, SAIVS integrates the pump directly into the tool body.

This compact configuration improves usability across a wide range of applications.

Advantages of Integral Hydraulic Pump Design

Compact construction

Eliminates the need for separate pumps, making the tool easier to handle in restricted workspaces.

Rapid deployment

Operators can begin spreading immediately without additional setup steps.

Cleaner and safer job sites

Fewer components reduce trip hazards and improve overall site organization.

These benefits make integral pump flange spreaders ideal for shutdown maintenance, plant inspections, and emergency repairs.

Lightweight Construction with Industrial Strength

SAIVS flange spreaders are engineered for portability without compromising durability.

With typical tool weights ranging from 15 lbs to 19 lbs, technicians can easily transport and position equipment during demanding maintenance operations.

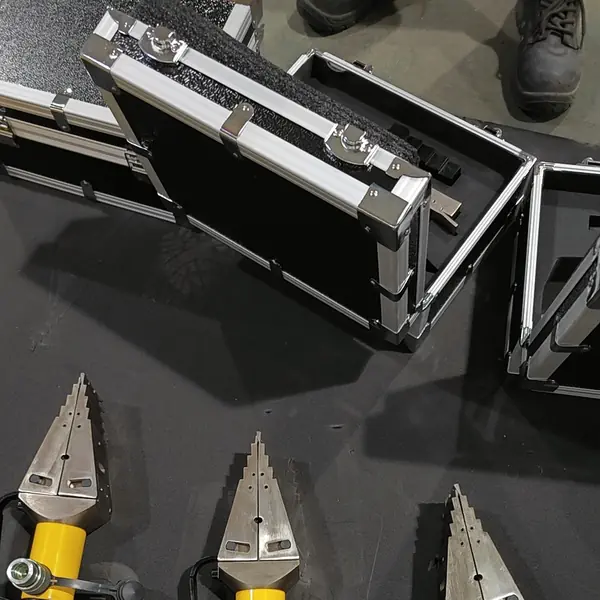

Each tool set is supplied in a reinforced molded carrying case, accommodating safety blocks, stepped blocks, lanyards, and technical documentation.

This organized packaging enhances efficiency and protects equipment during transport.

No-Gap Flange Spreaders for Zero-Access Applications

In many industrial environments, flanges are fully seated with no visible gap, making traditional separation methods unsafe or ineffective.

SAIVS no-gap flange spreaders are specifically engineered to address this challenge.

Using precision-machined collets that engage bolt holes directly, these tools initiate separation without prying or hammering.

Why No-Gap Technology Matters

Controlled initial separation

Force is applied evenly, minimizing stress on bolts and flange surfaces.

Reduced accident risk

Eliminates the need for improvised tools or unsafe manual techniques.

Wide industry compatibility

Designed for specific flange sizes, ensuring consistent performance across multiple applications.

Industry Trends Shaping Flange Spreader Demand

The global flange spreader market is evolving as industries adopt smarter maintenance practices.

Procurement decisions are increasingly driven by safety compliance, productivity, and long-term cost efficiency.

Smart Monitoring and Digital Integration

Future flange spreaders are expected to incorporate load sensors and monitoring systems.

These features will allow maintenance teams to document applied force and improve inspection traceability.

Focus on Ergonomics and Mobility

As maintenance work expands into offshore platforms and remote facilities, lightweight and portable tools will continue to gain preference.

Compact flange spreaders directly support this operational shift.

Safety-Driven Purchasing Decisions

Regulatory pressure and corporate safety standards are pushing organizations to invest in advanced tools.

Flange spreaders that minimize manual risk are becoming essential equipment rather than optional accessories.

SAIVS: Your Trusted Partner for Flange Spreader Solutions

At SAIVS, product development is guided by real maintenance challenges faced in the field.

Our flange spreaders are manufactured to deliver reliable performance, consistent force output, and superior safety.

By choosing SAIVS, industrial buyers gain access to tools designed for efficiency, durability, and long-term operational value.