HAWE Piston Pump Maintenance and Failure Analysis

Introduction:

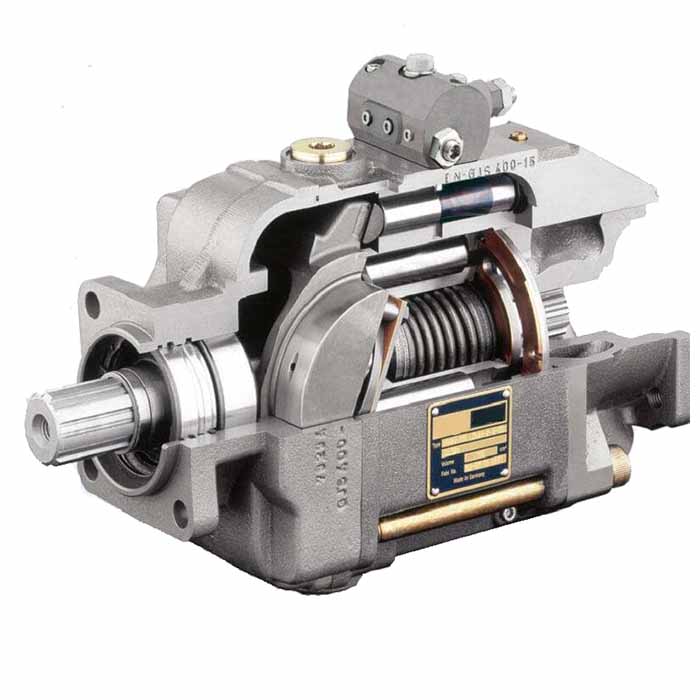

This article delves into the maintenance procedures and troubleshooting techniques for Hawei plunger pumps, widely used in modern Hydraulic Systems. Plunger pumps are positive displacement pumps that utilize a plunger to reciprocate within a cylinder, creating pressure and flow. Hawei plunger pumps are known for their reliability and efficiency, making them a popular choice in various applications.

Maintenance Practices:

Regular Inspection: Conduct routine inspections to identify potential issues early on. Check for signs of wear, leaks, or damage to components like the swash plate, plungers, and seals.

Cleanliness: Maintain a clean working environment to prevent contamination of the hydraulic system. Use clean, high-quality hydraulic fluid and replace filters regularly.

Proper Lubrication: Ensure adequate lubrication of bearings and moving parts to minimize friction and wear. Follow the manufacturer's recommended lubrication schedule and guidelines.

Preventive Maintenance: Implement preventive maintenance practices, including regular oil changes, filter replacements, and component inspections. This proactive approach can help prevent breakdowns and extend the pump's lifespan.

Troubleshooting Common Faults:

Low Output Pressure:

a. Swash Plate Wear: Excessive wear on the swash plate can lead to reduced pressure generation. Inspect the swash plate for signs of wear and replace it if necessary.

b. Internal Leaks: Internal leaks can cause pressure loss and reduced pump efficiency. Check for leaks at seals, joints, and connections.

c. Valve Malfunction: Faulty valves can restrict oil flow and affect pressure. Inspect and replace valves if necessary.

Excessive Noise:

a. Air Entrainment: Air in the hydraulic system can cause cavitation and noise. Check for air leaks and bleed the system if necessary.

b. Worn Bearings: Worn bearings can generate noise due to increased friction. Replace bearings if necessary.

c. Improper Alignment: Misalignment between the pump shaft and motor shaft can cause vibration and noise. Check alignment and adjust if necessary.

Incorrect Output Flow:

a. Swash Plate Angle Issues: Improper swash plate angle can affect flow rate. Check the swash plate angle adjustment mechanism and ensure proper operation.

b. Valve Sticking: Sticking valves can restrict oil flow and affect output flow. Clean and lubricate valves or replace them if necessary.

c. Control System Faults: Issues with the control system can cause erratic flow behavior. Check sensors, actuators, and control electronics for proper operation.

Leaks:

a. Seal Failure: Worn or damaged seals can lead to leaks at various points in the pump. Replace seals as needed.

b. Loose Connections: Loose connections at fittings, pipes, or joints can cause leaks. Tighten all connections securely.

c. Cracked or Damaged Components: Cracks or damage to pump components like the housing or plungers can lead to leaks. Inspect components thoroughly and replace if necessary.

Conclusion:

Maintaining Hawei plunger pumps properly and promptly addressing any faults can ensure optimal performance, extend pump lifespan, and minimize downtime. By following these guidelines and adhering to manufacturer recommendations, you can effectively maintain the reliability and efficiency of your Hawei plunger pumps.

Additional Considerations:

Consult Manufacturer's Manual: Refer to the manufacturer's specific instructions for detailed maintenance procedures and troubleshooting guidance.

Seek Professional Assistance: For complex issues or major repairs, consider involving qualified technicians or hydraulic system specialists.

By implementing these comprehensive maintenance and troubleshooting practices, you can ensure the smooth operation and long-lasting performance of your Hawei plunger pumps.