Basic composition of hydraulic torque wrench

Hydraulic Torque Wrench is composed of body, electrohydraulic pump, dual high-pressure oil pipe and strength sleeve. After starting, the hydraulic pump generates pressure through the motor, transfers the internal hydraulic fluid to the Hydraulic torque wrench through the oil pipe medium, then pushes the piston rod of the hydraulic torque wrench. The piston rod drives the ratchet at the front of the wrench so that the ratchet can drive the drive shaft to complete the pre-tension and loosening of the bolt.

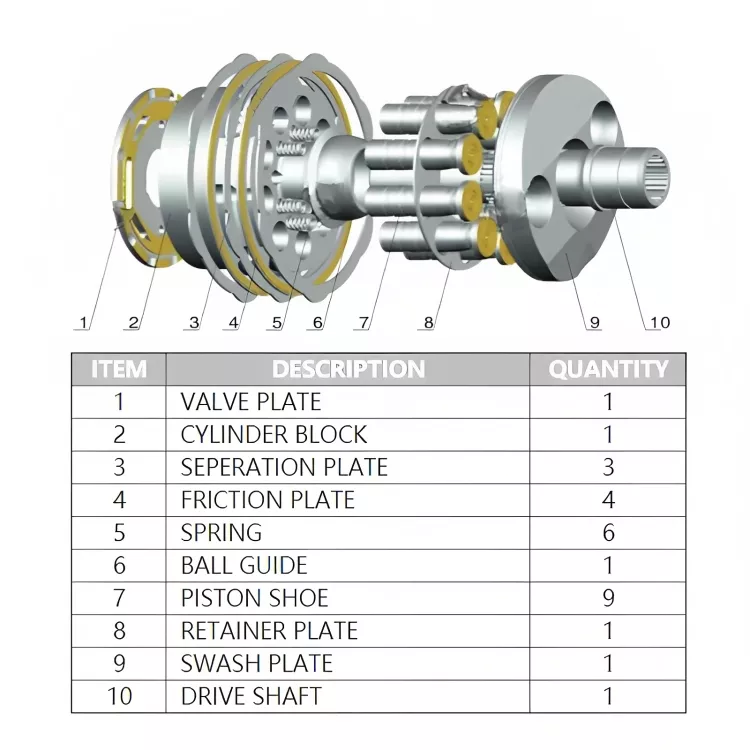

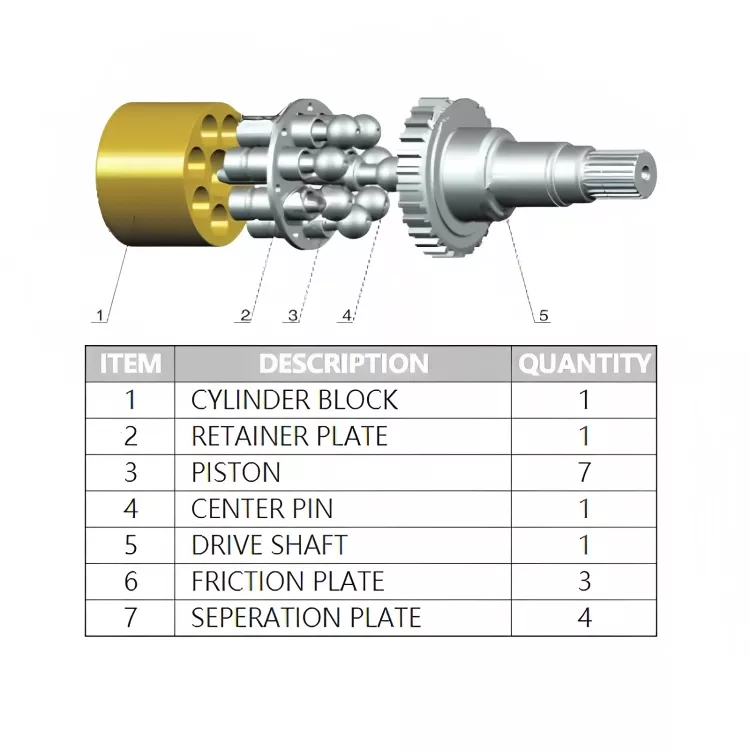

The special pump for hydraulic torque wrench can be driven either electrically or pneumatically. The body of the hydraulic torque wrench consists of three parts, the body (also called the housing), the cylinder and the transmission parts. Cylinder output force, cylinder piston rod and drive component constitute the motion pair. The distance between cylinder A and drive component A is the hydraulic wrench amplifying arm. Cylinder output times the force arm, which is the theoretical output torque of hydraulic wrench.

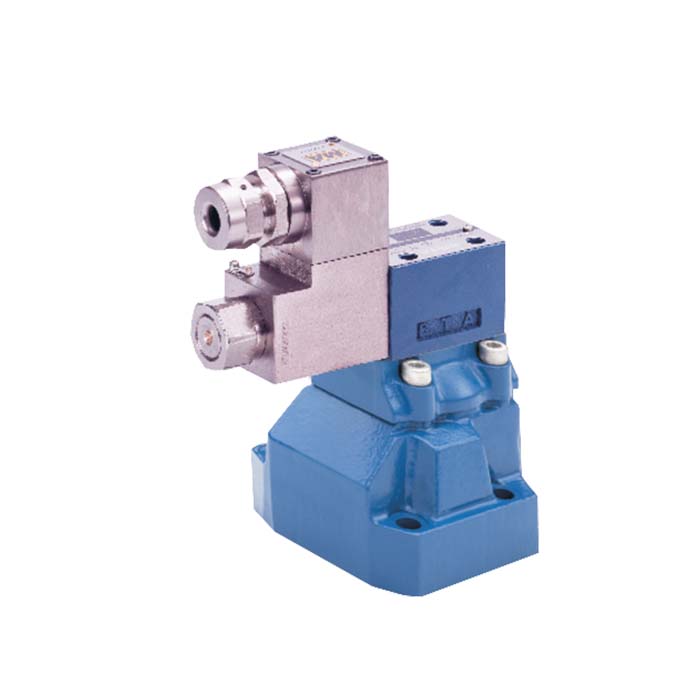

The hydraulic wrench pump is the power unit of the hydraulic wrench. Hydraulic wrench pump is a high-pressure pump with working pressure of 70MPa. The common pumps are electrohydraulic pump and pneumatic hydraulic pump. Hydraulic wrench pump is composed of motor (motor or gas motor), pump, pipeline, electrical control, etc. Common pumps are two-stage pumps and three | stage pumps. Common two-stage pumps are low pressure gear pumps and high pressure piston pumps. The gear pump provides pressurized hydraulic oil for the piston pump, and the change pressure between the gear pump and the piston pump is 7-10MPa. Three | stage pumps have various structures, typical of which are all piston pumps, 4 large diameter pistons at low pressure, 2 small diameter pistons at medium pressure and 2 small diameter pistons at high pressure. There are also three | stage pumps with one | stage pump as gear pump and two and three | stage pump as piston pump. The first | stage, the second | stage and the third | stage of the three | stage pump are respectively called low pressure, medium pressure and high pressure. When the hydraulic wrench works on the piston, it is generally in medium pressure state of 10-32 MPa, while the medium pressure flow is 2.2 times of the high pressure flow (32-70 MPa). Combined with the three | stage pressure flow curve, the speed of the three | stage flow pump is nearly 2 times that of the two-stage flow pump. It can be seen that the speed of the third | stage pump is much faster than that of the second stage pump.

The electric hydraulic wrench pump motor is divided into carbon brushless motor and carbon brush motor. Brushless motors are induction motors and need capacitance. In order for the pump to start under pressure, start-up capacitance and running capacitance need to be installed. Brush motors are usually series-excited motors with high speed, which can provide a large flow rate for the pump, but with high noise and vibration. Carbon brushless motors usually have a service life of tens of thousands of hours, but are very likely to cause overheating of the motor. According to different operating conditions, it is not a very effective option. The continuous service life of carbon brush motors is 1-10 years and they are usually equipped with cold | coolers. Therefore, carbon brush motors are more suitable for long-term continuous operation of special pumps for hydraulic wrenches. Moreover, these pumps are mainstream configurations. The main purpose of the hydraulic wrench synchronization system is to avoid the flange side unilateral compression mode, which can cause the flange side gaskets to fail due to excessive extrusion and thus cause leakage. The synchronization system is used when two or four hydraulic wrenches are connected to one pump at the same time. According to the hydraulic principle, when several hydraulic wrenches work at the same time and output the set torque, the flange can be closed in parallel with a torque accuracy of 3%. The synchronization system can lock the bolts at one time while the single system needs to be loaded several times and locked step by step. Thus, the efficiency of the synchronization system is much higher than that of the single system.